Flexible Packaging Films and Structures

Flexible packaging films are widely used for packaging various products such as food, pharmaceuticals, personal care, and household items. Depending on the packaging needs of the product, we will use different material structures. This is the most important thing when you make your own packaging.

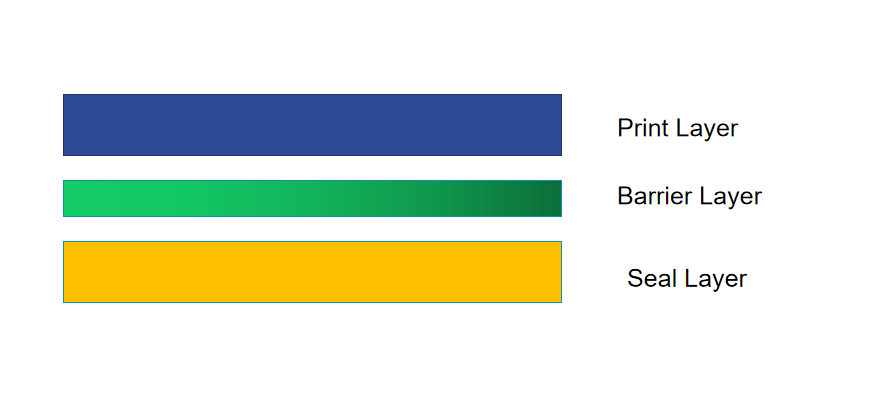

Structure of compound flexible packaging

A compound flexible package is a type of packaging that combines two or more different materials to create a single package that is both durable and flexible.

The compound flexible package may consist of a variety of materials, such as plastic, foil, paper, and other flexible materials. The combination of materials allows for the package to be customized to meet specific requirements for the product being packaged, such as the need for oxygen or moisture barrier, puncture resistance, or temperature resistance.

Print Layer

BOPET,Nylon/PA,BOPP

MOPP, PE, Kraft paper

Barrier Layer

Aluminium foil(AL), VMPET, PET. Nylon/PA, Kraft paper,EVOH,

Seal Layer

PE, CPP, PLA

Features of common flexible packaging films

If you are an online-only business and sell direct-to-consumer, then you will also need packaging solutions for shipping your products to your customers. There are all sorts of packaging options to choose from based on the types of products you manufacture and sell.

Polyethylene (PE) Film: This is one of the most commonly used packaging films, thanks to its versatility, durability, and cost-effectiveness. PE films can be made in different thicknesses and with different additives to provide specific properties such as moisture resistance, puncture resistance, and gas barrier properties.

Polypropylene (PP) Film: This film is also widely used in flexible packaging due to its excellent clarity, strength, and moisture barrier properties. PP films are also resistant to oils and chemicals, making them suitable for use in food packaging, medical packaging, and other applications.

Polyester (PET) Film: PET films are known for their high tensile strength and excellent barrier properties, making them ideal for packaging products that require high oxygen and moisture barriers, such as snack foods, coffee, and meat products.

Nylon (PA) Film: Nylon films offer excellent puncture resistance, durability, and barrier properties, making them suitable for packaging products that require protection from moisture, oxygen, and other gases.

Polyvinyl Chloride (PVC) Film: PVC films are known for their excellent clarity and flexibility, making them a popular choice for packaging products such as meat, dairy, and baked goods. PVC films are also resistant to oil and grease, making them suitable for use in food packaging.

Ethylene Vinyl Alcohol (EVOH) Films: EVOH films have excellent oxygen barrier properties, making them suitable for packaging products that require extended shelf life, such as snacks, dairy products, and beverages.

Aluminum Foil Films: Aluminum foil films provide excellent moisture and oxygen barrier properties and are commonly used for packaging perishable food items such as coffee and nuts.

Metallized films: These films are typically made of a combination of plastics and metal, providing excellent barrier properties against moisture, oxygen, and light. They are commonly used for packaging coffee, tea, and other perishable food products.

- Polylactic Acid (PLA), also known as poly-lactide, belongs to the polyester family. It is a polymer obtained by polymerizing lactic acid, which is mainly derived from abundant and renewable sources such as corn and cassava. The production process of PLA is pollution-free, and the product is biodegradable, achieving a cycle in nature. Therefore, it is an ideal green polymer material.

Paper and paperboard: These materials are commonly used for packaging dry goods, such as cereal, pasta, and crackers. They are also widely used for packaging pharmaceutical products and cosmetics.

These are just a few of the many flexible packaging materials available. The choice of material will depend on the specific application and product requirements.

Common structure of compound flexible packaging

Flexible packaging materials are commonly used in the food, pharmaceutical, and consumer goods industries due to their versatility, convenience, and cost-effectiveness. Some common flexible packaging structures include,

Common Strutures | Usage |

| OPP/VMPET/PE | Dry food,powder, coffee, and etc |

| OPP/CPP | Components, dry food |

| PET/VMPET/PE | Dry food, powder, coffee, and etc |

| PET/AL/PE | Need high barrier product |

| MOPP/VMPET/PE | Dry food, powder, coffee, and etc |

| PE/EVOH/PE, PE/PE | Recyclable Package |

| MOPP/Kraft paper/VMPET/PE | Dry food, snack |

| PA/AL/RCPP | Boiling Cooking Product |

| PA/PE,PET/Nylon/PE | Frozen or liquid product |

| Kraft paper/PLA, Kraft paper/VMPLA/PLA | Compostable Packaging |

Click Here to know more about us. or you can also view our Youtube video to know more.

KX package can help you create the most suitable solution for your product