Knowledge on the Use of Plastic Packaging Bags

Plastic packaging bags are an essential component of modern packaging solutions across various industries. They offer versatility, convenience, and protection for a wide range of products, from food items to consumer goods. Understanding the various aspects of plastic packaging bags, including their types, materials, applications, and sustainability considerations, is crucial for businesses aiming to optimize their packaging strategies. In this article, we will explore key knowledge related to the use of plastic packaging bags.

1. Types of Plastic Packaging Bags

Plastic packaging bags come in various types, each designed for specific applications. Some common types include:

Flat Bags: These simple bags are designed to be filled from the top and sealed. They are often used for bulk packaging of items like grains and produce.

Gusseted Bags: Featuring side gussets that allow them to expand, gusseted bags can stand upright and hold more volume. They are commonly used for snacks and bulk goods.

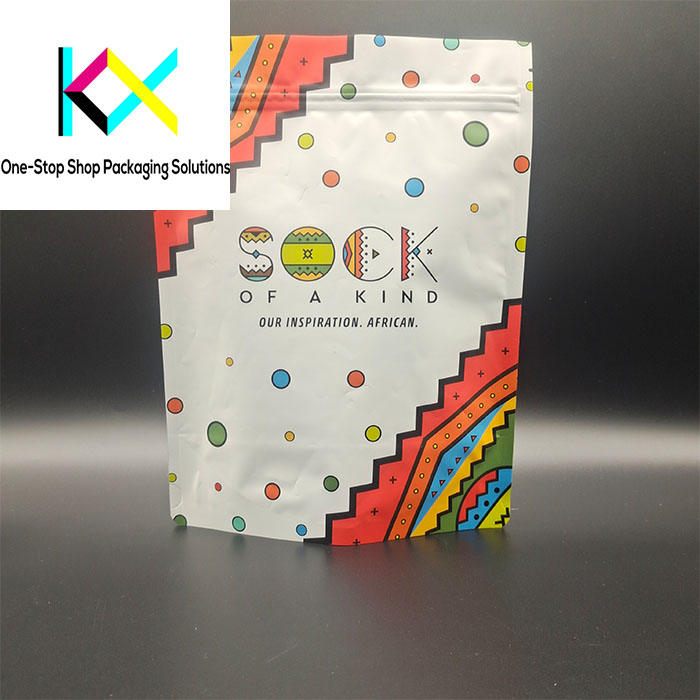

Pouch Bags: These bags are often resealable and can feature a stand-up design. Pouch bags are popular for consumer products, as they offer convenience and brand visibility.

Woven Bags: Made from woven polypropylene, these bags are durable and breathable, making them suitable for heavy items like fertilizers and grains.

Valve Bags: Designed for efficient filling of bulk products, valve bags have a built-in valve that allows for fast packing, commonly used for powders and grains.

2. Materials Used in Plastic Packaging Bags

The materials used in plastic packaging bags significantly affect their performance and suitability for different applications. Some common materials include:

Polyethylene (PE): Known for its flexibility and moisture resistance, PE is widely used in various types of bags, including flat and gusseted bags.

Polypropylene (PP): Offering higher strength and clarity than PE, PP is commonly used in pouches and woven bags. It provides excellent barrier properties.

BOPP (Biaxially Oriented Polypropylene): This material is known for its strength and clarity, making it ideal for packaging products where visibility is important, such as snacks and candies.

Compostable Plastics: As sustainability becomes a growing concern, some manufacturers are turning to compostable materials that break down in composting conditions, providing an eco-friendly option for packaging.

3. Applications of Plastic Packaging Bags

Plastic packaging bags are utilized in numerous industries, each with specific needs. Common applications include:

Food Packaging: Plastic bags are widely used for packaging snacks, frozen foods, and bulk items. Their barrier properties help preserve freshness and extend shelf life.

Retail Packaging: In retail, plastic bags serve as an effective way to package consumer goods, allowing brands to showcase their products while ensuring protection.

Agricultural Packaging: Woven and valve bags are often used for agricultural products, such as grains and fertilizers, due to their strength and durability.

Medical and Pharmaceutical: Plastic bags are also used for packaging medical supplies, ensuring sterility and protection during transportation.

4. Digital Print Packaging

One of the most significant advancements in the packaging industry is the rise of digital print packaging. This technology allows for high-quality, customizable prints directly on plastic packaging bags. Brands can easily create vibrant designs, logos, and product information, enhancing shelf appeal and consumer engagement. Digital printing also enables shorter production runs, making it feasible for brands to experiment with limited-edition packaging or seasonal designs without incurring high costs.

5. Sustainability Considerations

With growing environmental awareness, the sustainability of plastic packaging has come under scrutiny. Companies are increasingly seeking ways to minimize their environmental impact. Here are some considerations:

Recyclability: Many plastic packaging bags are recyclable, but it’s essential for consumers to know the proper disposal methods to ensure recycling. Using recyclable materials can significantly reduce waste.

Reduced Plastic Usage: Businesses can explore ways to minimize plastic use by opting for thinner bags without compromising strength and functionality.

Alternative Materials: Companies are investing in research and development to create biodegradable and compostable plastics that offer an eco-friendly alternative to traditional plastic.

Consumer Education: Educating consumers about the importance of recycling and responsible disposal can contribute to more sustainable practices.

6. Key Benefits of Plastic Packaging Bags

Plastic packaging bags offer numerous advantages that contribute to their widespread use:

Cost-Effectiveness: Compared to other packaging options, plastic bags are often more affordable, making them an attractive choice for manufacturers.

Lightweight: Plastic bags are lightweight, reducing shipping costs and the environmental impact associated with transportation.

Versatility: The range of available sizes, shapes, and materials allows for endless customization, meeting the unique needs of various products.

Durability: Plastic bags are resistant to moisture, tears, and punctures, ensuring product protection during storage and transportation.

Conclusion

Understanding the various aspects of plastic packaging bags is essential for businesses looking to optimize their packaging strategies. With a wide range of types and materials, along with advancements like digital print packaging, companies can create effective and appealing packaging solutions. As sustainability continues to shape consumer preferences, the industry must adapt and innovate to meet these challenges. By embracing eco-friendly practices and educating consumers, businesses can contribute to a more sustainable future while maximizing the benefits of plastic packaging bags.

You can visit our website to know more about our flexible packaging pouch: