Do Custom Packaging Bags Require Sampling? The Answer is Here

When creating custom packaging bags for a product, one of the key decisions businesses must make is whether to go through a sampling phase before committing to a full production run. Sampling, in the context of packaging, refers to the process of creating a prototype or small batch of the packaging to evaluate various elements such as design, material quality, and functionality. This article will explore the importance of sampling in custom packaging, with a particular focus on how digital printing technology plays a crucial role in the process.

1. Why Sampling is Crucial for Custom Packaging Bags

Sampling is a critical step in the packaging development process for several reasons. When designing custom packaging, you want to ensure that the final product meets your expectations in terms of quality, functionality, and design. For businesses looking to create a unique identity through packaging, a sample provides a tangible opportunity to see, touch, and test the packaging before committing to a large-scale production run.

Some of the key factors that are evaluated during the sampling stage include:

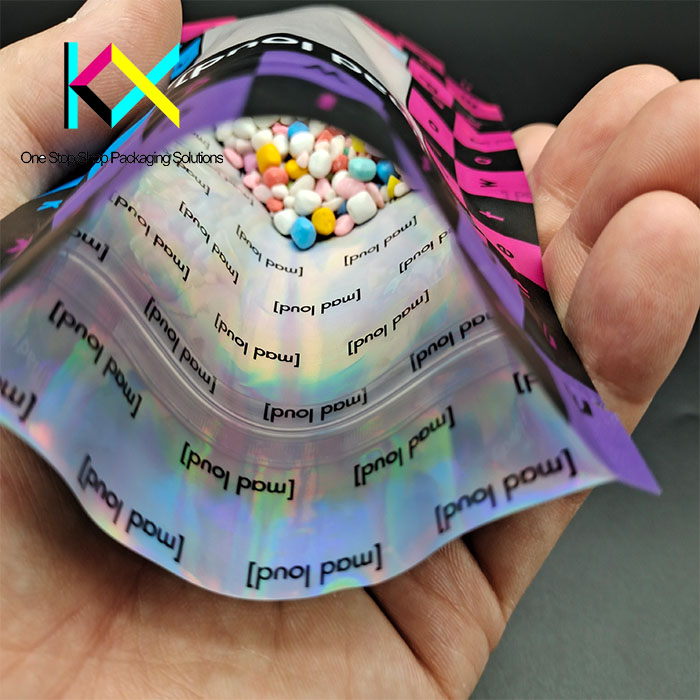

Material Quality: Custom packaging bags come in a variety of materials, such as plastic, paper, or biodegradable options. Sampling allows businesses to assess whether the material is durable, flexible, and appropriate for the product it will hold.

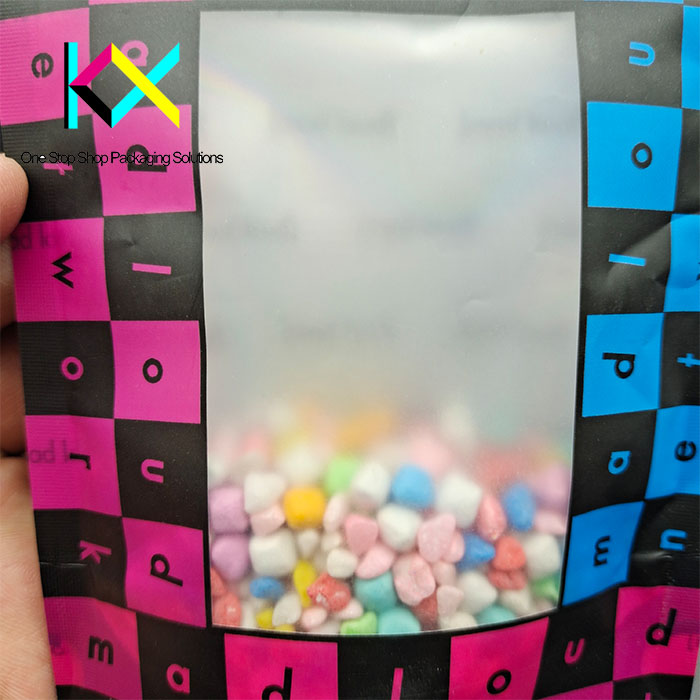

Print Quality: Packaging is often a key marketing tool, and the print quality on custom packaging bags plays a vital role in branding. By creating a sample, businesses can check the clarity of logos, text, colors, and other design elements.

Design and Fit: A sample allows companies to verify the design’s functionality. For instance, is the bag the right size for the product? Does the design allow for easy storage, shipping, and consumer use?

Compliance and Safety: Ensuring that the packaging meets all relevant regulatory and safety standards is essential. A sample helps to verify that the packaging complies with industry requirements for food safety, environmental standards, and other regulations.

2. The Role of Digital Printing in the Sampling Process

Digital printing technology has transformed the packaging industry, particularly when it comes to custom packaging. Traditional printing methods like offset printing or flexographic printing require the creation of physical printing plates, making the sampling process time-consuming and expensive. Digital printing, on the other hand, allows for quick, cost-effective, and high-quality prototypes to be produced with minimal setup.

Here’s how digital printing enhances the custom packaging sampling process:

Speed and Efficiency: Digital printing enables rapid production of packaging samples. Since no printing plates are required, the setup process is faster compared to traditional methods. This means businesses can get a physical sample within days, allowing for quick feedback and iterations in design. Whether you’re working with a small run or testing different design variations, digital printing provides an efficient solution for sampling.

High-Quality Prints: Digital printing can produce vibrant, high-resolution images with fine details. This is especially important when evaluating the final design of custom packaging. Brands can test how logos, product information, and artwork look on the bag material and ensure that the print quality meets expectations.

Customization and Flexibility: One of the key benefits of digital printing is its ability to handle customization without additional costs. With traditional printing methods, small batch runs or last-minute changes may require significant setup costs. Digital printing, however, allows for easy modifications to the design, making it a great option for businesses that need to experiment with different color schemes, logos, or even variable data (like batch numbers or expiration dates) during the sampling phase.

Cost-Effective Sampling: Since digital printing eliminates the need for expensive printing plates, it makes producing small runs or samples more affordable. This cost efficiency is particularly beneficial for businesses that may need several samples or want to test various designs before finalizing their packaging.

Material Compatibility: Digital printing works well on a variety of materials used for packaging bags, including paper, plastic, and biodegradable films. Whether you’re designing a plastic pouch or a paper bag, digital printing can provide consistent results across different substrates.

3. The Benefits of Sampling with Digital Printing

Sampling with digital printing offers several advantages that can lead to a more successful custom packaging design:

Reduced Risk: Sampling helps mitigate the risk of making costly mistakes in a full production run. By creating prototypes, businesses can detect any potential issues with design, material, or print quality before proceeding with a larger batch, saving both time and money in the long run.

Faster Time-to-Market: With digital printing, the time between designing a custom packaging bag and receiving the final sample is significantly reduced. This faster turnaround can help businesses get their products to market quickly, especially when they need to meet seasonal deadlines or respond to market trends.

Better Decision Making: Having a physical sample of the custom packaging allows businesses to make more informed decisions. Seeing and holding the sample gives a clearer understanding of how the packaging will look and feel in real-world conditions, which can’t always be fully assessed through digital mockups alone.

Customer Feedback: If the product will be sold directly to consumers, sampling provides the opportunity to gather feedback from test groups or focus groups. This input can help refine the design before it is launched on a larger scale, ensuring the packaging resonates with the target market.

4. Conclusion

While creating custom packaging bags is an exciting and essential part of product development, it’s important not to overlook the sampling phase. Sampling allows businesses to evaluate material quality, print clarity, design functionality, and overall safety before committing to full-scale production. Digital printing technology makes the sampling process faster, more cost-effective, and highly flexible. By providing high-quality prototypes in a short period, digital printing ensures that brands can test their custom packaging designs efficiently, minimizing the risk of errors and ensuring that the final product meets all expectations. For businesses seeking to create visually striking, functional, and safe custom packaging, digital printing is an indispensable tool that elevates the entire process.

You can visit our website to know more about our flexible packaging pouch: