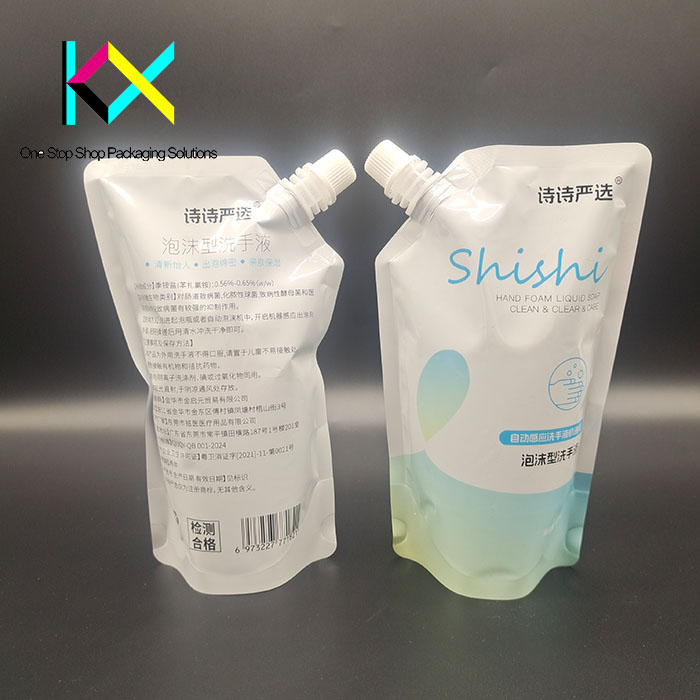

Recyclable Spout Pouches: Pioneering Sustainable Liquid Packaging Solutions

The packaging industry stands at a critical juncture where environmental responsibility meets innovative design. Recyclable spout pouches have emerged as a transformative solution, offering brands an effective way to package liquids while addressing pressing sustainability concerns. Alongside complementary formats like brown kraft paper stand up pouches and eco stand up pouches, these packaging innovations are reshaping product delivery systems across multiple sectors.

Technical Advancements in Spout Pouch Design

Modern recyclable spout pouches incorporate several groundbreaking features:

Material Science Innovations

Mono-material polyethylene constructions achieving 95% recyclability rates

Nano-coating technologies providing oxygen barriers below 0.5 cc/m²/day

Integrated valve systems for precise liquid dispensing

Performance Enhancements

Leak-proof spouts tested to withstand pressures up to 15 psi

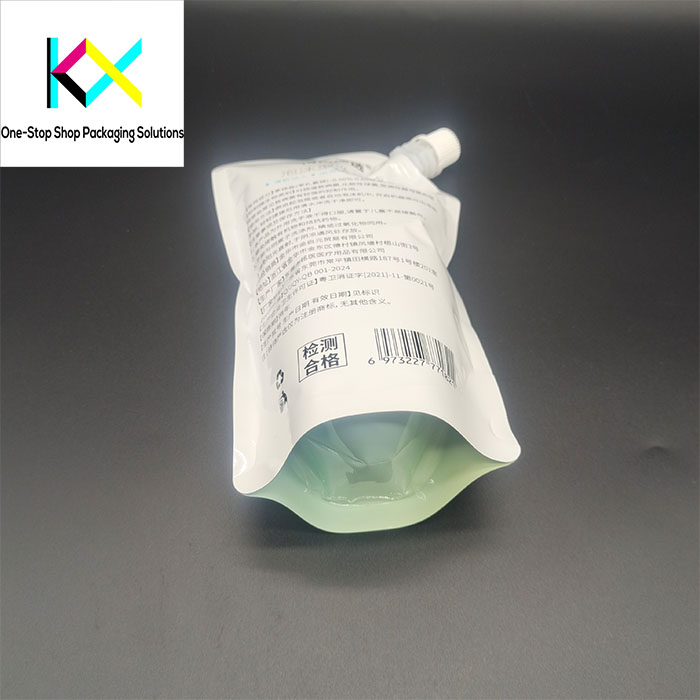

Ergonomic designs enabling 98% product evacuation

Tamper-evident features meeting pharmaceutical standards

Sustainability in Practice

The environmental benefits of recyclable spout pouches extend beyond basic recyclability:

Carbon Footprint Reduction

Compared to rigid plastic bottles, these pouches demonstrate:

60% less material usage

45% lower transportation emissions

30% reduced energy in productionCircular Economy Integration

Leading manufacturers now offer:

Take-back programs with 90% recovery rates

Chemical recycling compatibility

Upcycling initiatives for post-consumer materials

Complementary Packaging Formats

-

Brown Kraft Paper Stand Up Pouches

-

Ideal for dry goods with 12-18 month shelf life requirements

-

Compatible with modified atmosphere packaging

-

Custom printing options achieving 98% color accuracy

-

Eco Stand Up Pouches

-

Bio-based materials reaching 85% renewable content

-

Home-compostable certifications in major markets

-

Marine-degradable options breaking down in 12 weeks

-

Liquid Stand Up Pouches

-

Viscosity-specific spout designs (50-10,000 cPs)

-

Aseptic filling capabilities extending shelf life to 24 months

-

FDA-compliant materials for food and pharmaceutical use

Industry Applications

Food & Beverage

-

Cold-pressed juices achieving 40% longer freshness

-

Dairy alternatives reducing packaging weight by 60%

-

Cooking oils with precision-pour spouts

Personal Care

-

Shampoos demonstrating 30% less product waste

-

Lotions with airless dispensing systems

-

Travel-friendly sizes meeting TSA requirements

Household Products

-

Concentrated cleaners reducing water shipment

-

Child-safe closures for hazardous materials

-

Refill systems cutting packaging waste by 80%

Implementation Considerations

-

Filling Line Compatibility

-

Requires evaluation of:

VFFS machine adaptability

Spout attachment mechanisms

Liquid viscosity parameters

-

Supply Chain Optimization

-

Pallet configuration increasing load efficiency by 35%

-

Reduced warehouse space requirements

-

Lower freight costs through lightweighting

-

Consumer Education

-

QR codes linking to recycling instructions

-

On-pack disposal graphics

-

Retailer take-back programs

Future Outlook

Emerging technologies will further enhance recyclable spout pouches:

-

Smart sensors monitoring product freshness

-

Self-healing materials repairing minor punctures

-

Blockchain integration for material traceability

The transition to these sustainable packaging solutions represents both an environmental imperative and a market opportunity. Brands adopting recyclable spout pouches and related formats are positioning themselves as leaders in the new era of responsible packaging.

You can visit our website to know more about our compostable pouch: