Preserving Quality: The Evolution of Food Freshness Bags

In the dynamic landscape of food packaging, Food Freshness Bags have emerged as essential tools for extending shelf life and reducing waste. These specialized packages incorporate advanced materials and technologies to create optimal environments for perishable goods, balancing atmospheric conditions to slow spoilage while maintaining product quality. The development of modern Food Freshness Bags represents a significant advancement in food preservation, addressing both consumer demand for longer-lasting products and the industry’s need for sustainable solutions. As food supply chains become more complex and consumer expectations rise, the role of these bags continues to expand, making them indispensable in the global effort to reduce food waste.

The Fabric of Protection: How Textile Packaging Safeguards Value

In the intricate world of global commerce, Textile Packaging serves as a critical yet often overlooked component in preserving the quality and value of fabrics, garments, and technical textiles throughout the supply chain. This specialized field has evolved far beyond simple poly bags, incorporating advanced materials and engineered designs to address the unique vulnerabilities of textile products—from moisture and contamination to abrasion and static electricity. The development of modern Textile Packaging reflects a deep understanding of material science and logistics, ensuring that products arrive in pristine condition regardless of the journey’s length or complexity. As sustainability concerns and e-commerce demands reshape the industry, Textile Packaging continues to adapt, balancing protective functionality with environmental responsibility.

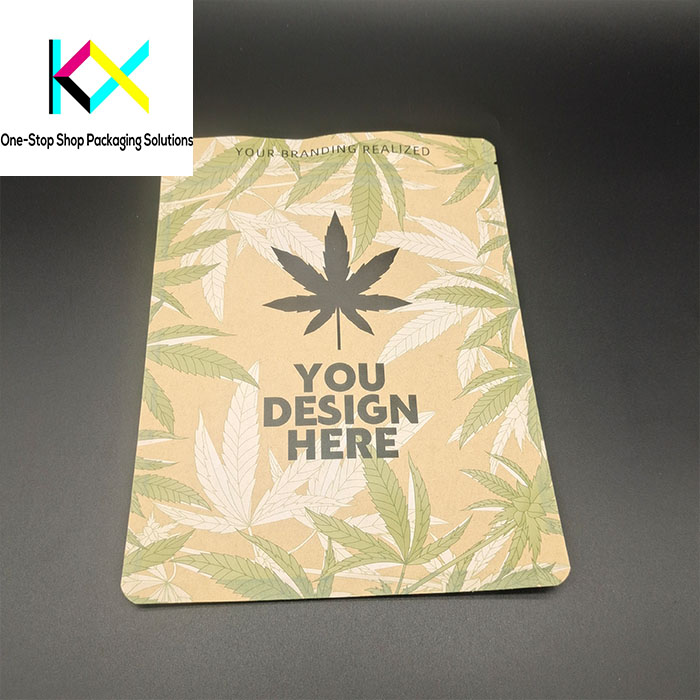

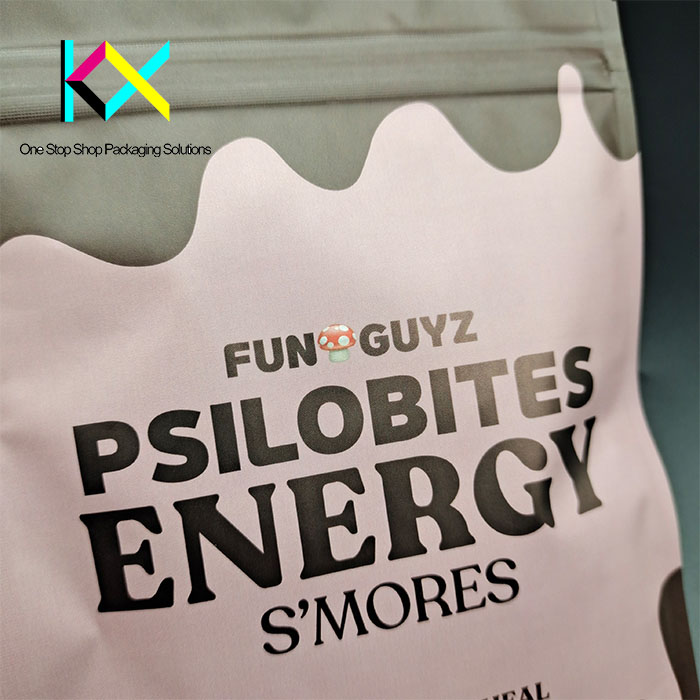

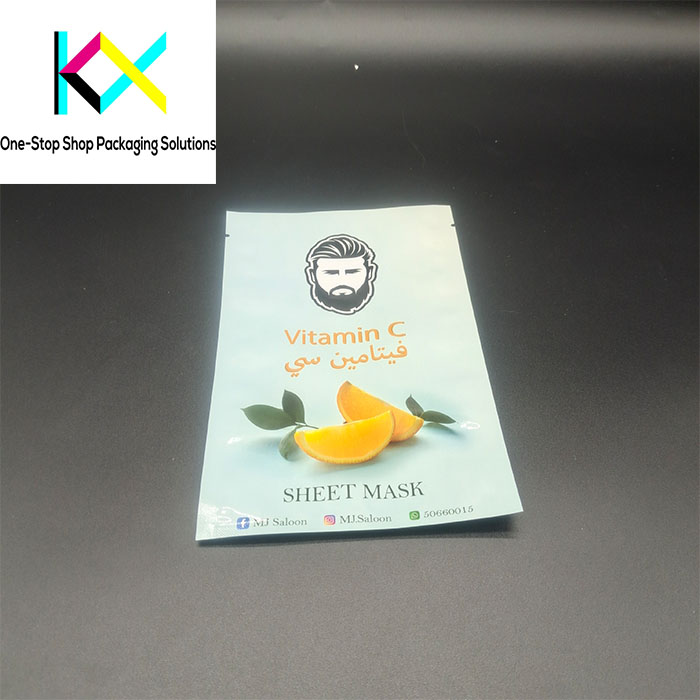

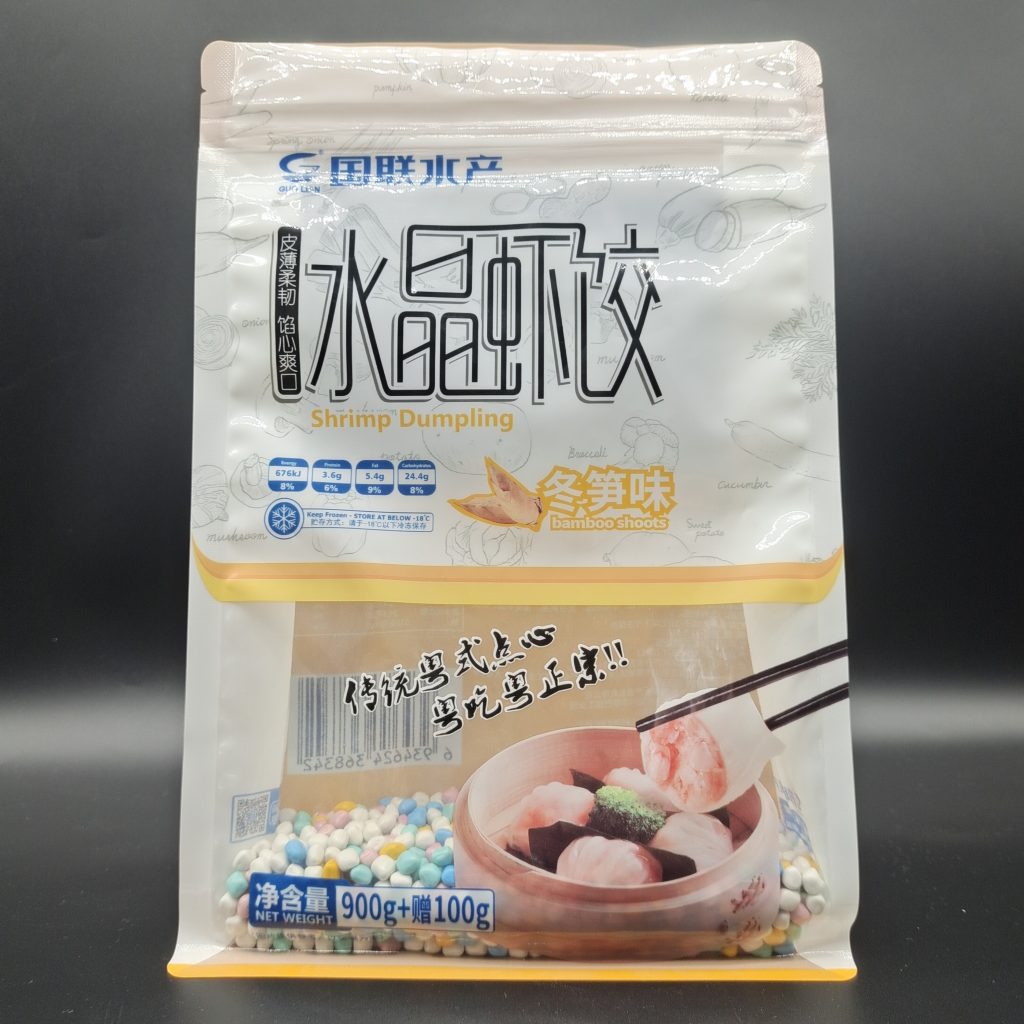

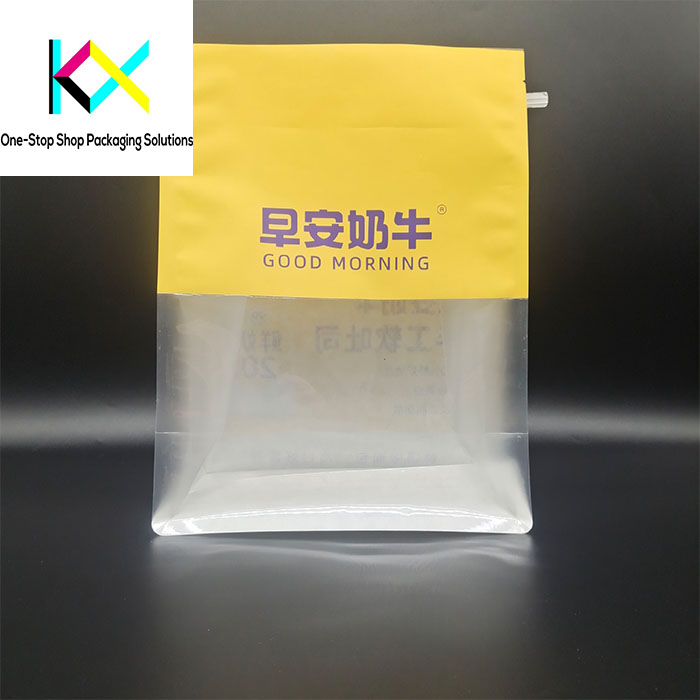

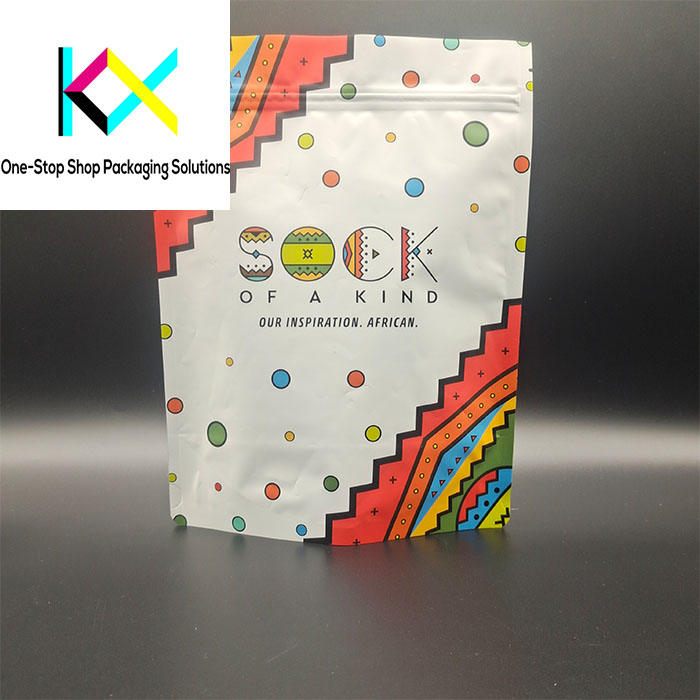

The Art of Attraction: How Visual Packaging Captivates Consumers

In today’s crowded marketplace, Visual Packaging has evolved from mere container to powerful communicator, serving as a silent salesperson that must attract, inform, and persuade within seconds. This critical marketing tool combines aesthetics, functionality, and brand storytelling to create memorable consumer experiences that drive purchasing decisions. The effectiveness of Visual Packaging hinges on its ability to stand out on shelves while conveying quality and brand values through strategic design elements, material choices, and structural innovation. As shopping behaviors evolve, particularly with the growth of e-commerce, the role of Visual Packaging has expanded beyond physical retail to create shareable digital moments that extend brand reach through social media.

The Unseen Facilitators: How Release Films Enable Modern Manufacturing

In the intricate world of industrial materials, Release Films play a critical yet often overlooked role. These specialized films act as protective barriers, ensuring that sensitive surfaces remain uncontaminated during manufacturing processes such as composite curing, adhesive application, and molding. The performance of Release Films is paramount; they must provide a consistent, clean release without transferring any residue or affecting the material beneath. As industries from aerospace to renewable energy demand higher precision and reliability, the evolution of Release Films continues to be driven by advancements in material science and surface engineering, making them indispensable in high-tech production environments.

How E-commerce Packaging is Being Reinvented

The dramatic rise of online shopping has thrust E-commerce Packaging into the spotlight, transforming it from a mere protective shell into a critical brand touchpoint and sustainability battleground. This specialized segment of the packaging industry must solve a complex equation: ensuring products survive the brutal logistics journey while minimizing material waste and environmental impact. The evolution of E-commerce Packaging is being driven by consumer expectations, regulatory pressures, and the sheer economic imperative of optimizing shipping costs, leading to innovations that prioritize both function and responsibility in equal measure.

The Dual Challenge: How Plastic Bags and Candy Packaging Are Adapting to a New Era

The humble Plastic Bags remains one of the most visible and controversial symbols of the packaging industry’s environmental impact. Yet, despite mounting regulatory pressure and shifting consumer sentiment, these lightweight workhorses continue to play a critical role in global commerce, particularly in the food and retail sectors. Their evolution, however, is undeniable. The industry is actively reengineering the very essence of Plastic Bags, moving from single-use convenience items towards more durable, reusable, and ultimately recyclable solutions that align with the principles of a circular economy. This transformation is not happening in isolation; it reflects a broader shift affecting all flexible packaging, including the vibrant and technically demanding world of candy packaging.

The Seamless Cycle: How Recyclable Packaging Builds a Circular Future

The pursuit of sustainability in the packaging industry has moved beyond a trend into a fundamental business imperative, and at the heart of this transformation lies Recyclable Packaging. This is no longer just about adding a recycling symbol to a package; it represents a comprehensive redesign of materials, processes, and systems to ensure packaging can be efficiently collected, processed, and reborn as new products. The modern concept of Recyclable Packaging demands a holistic approach, considering the entire lifecycle from production to reprocessing, and it is reshaping how brands, manufacturers, and consumers think about product delivery and environmental responsibility.

How Clamshell Packaging is Evolving for Modern Markets

In the world of product presentation and security, Clamshell Packaging has long been a dominant force. Recognizable for its hinged design that “closes” like a clam, this packaging format offers unparalleled product visibility, theft deterrence, and physical protection for a vast range of goods. However, the traditional narrative around Clamshell Packaging is shifting. No longer just a clear plastic shell, it is evolving under pressure from sustainability mandates, e-commerce demands, and technological integration, transforming from a simple container into a sophisticated brand asset that balances function with responsibility.

How Single-Use Packaging is Evolving for a Circular Future

The conversation around Single-Use Packaging is at a critical crossroads. Once synonymous with convenience and disposability, the entire concept is being radically reimagined under pressure from regulators, consumers, and a collective drive for sustainability. However, the solution isn’t as simple as elimination. For many applications, particularly in food, healthcare, and hygiene, Single-Use Packaging remains essential for safety, preservation, and distribution. The industry’s challenge—and its greatest innovation opportunity—is transforming this packaging category from a linear liability into a circular asset, designing it for optimal functionality and a responsible end-of-life.

The Invisible Guardian: How Moisture Barrier Packaging Protects Our Global Supply Chain

In the complex world of product preservation, Moisture Barrier Packaging serves as an invisible yet critical line of defense against one of nature’s most persistent threats: water vapor. This specialized packaging technology has evolved far beyond basic protection, becoming a sophisticated solution that safeguards everything from pharmaceuticals and electronics to agricultural products and premium foods. The development of advanced Moisture Barrier Packaging represents a remarkable convergence of material science and practical engineering, creating formidable barriers that maintain product integrity throughout extended supply chains and challenging environmental conditions. As global trade expands and consumer expectations rise, the role of Moisture Barrier Packaging becomes increasingly vital to product quality and safety.

The Hybrid Horizon: How Paper-Plastic Composite Packaging is Redefining Sustainability

In an industry constantly navigating the complex trade-offs between performance, cost, and environmental impact, one solution is gaining remarkable traction: Paper-Plastic Composite Packaging. This innovative material architecture strategically layers the strength and barrier properties of plastic with the rigidity, printability, and perceived sustainability of paper. It represents a pragmatic evolution, moving beyond pure materials to create hybrids that better address modern consumer and regulatory demands. The growth of Paper-Plastic Composite Packaging is not just a trend; it’s a clear response to the urgent need for reducing plastic use while maintaining the functionality that protects products and ensures shelf life.

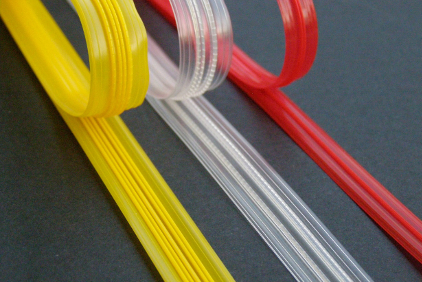

Unsealing Innovation: How Ziplock Bags & Stretch Film Are Reinventing Flexible Packaging

Far from being just pantry staples, Ziplock Bags are experiencing a significant evolution, driven by shifting consumer habits and industrial demands. Modern Ziplock Bags are shedding their purely domestic image, emerging as versatile, high-performance solutions across diverse sectors. Innovations focus on enhanced barrier properties – protecting contents from moisture, oxygen, and contaminants for extended periods. Crucially, the convenience of the resealable closure remains paramount, but now incorporates features like wider, more robust tracks for easier opening and closing, even with gloves or wet hands. The expansion into industrial applications, from organizing hardware components to protecting delicate electronic parts during assembly, highlights the growing versatility of these familiar Ziplock Bags. Their adaptability makes them indispensable in settings far beyond the kitchen.

Beyond the Pouch: How Gusset Bags & Blister Packaging Are Shaping Flexible Futures

The Unfolding Advantage: Gusset Bags Lead the Charge

The landscape of product packaging is in constant flux, driven by consumer demands, e-commerce logistics, and sustainability imperatives. Within this dynamic environment, Gusset Bags have emerged as a surprisingly versatile and increasingly vital player. Far more than just stand-up pouches, modern Gusset Bags leverage their unique side or bottom folds to offer significant advantages that align perfectly with contemporary needs. Their ability to stand upright enhances shelf presence, while the expanded capacity relative to footprint minimizes material use – a key sustainability win. Crucially, the gusset structure allows these bags to lie flat during shipping and storage, dramatically reducing transportation volume and costs, a factor paramount in today’s e-commerce-driven world. This inherent efficiency makes Gusset Bags a compelling choice for brands looking to optimize logistics and reduce environmental impact simultaneously.

Double Layer Bags: The Strategic Sweet Spot in an Era of Layered Performance Demands

In the dynamic world of flexible packaging, finding the optimal balance between performance, cost, and sustainability is paramount. Double Layer Bags represent a crucial middle ground, offering significant advantages over simpler structures while often avoiding the complexity and cost of their more robust counterparts. As market demands evolve and sustainability pressures intensify, understanding the strategic role of Double Layer Bags, alongside when Triple Layer Bags become essential, is critical for converters and brands navigating the future.

Stand-up Pouches: The Pinnacle of Convenience Meets the Rise of Simpler Solutions

The landscape of flexible packaging is defined by relentless innovation, driven by consumer demands for convenience, shelf impact, and sustainability. Stand-up Pouches have dominated this evolution, becoming the go-to format for countless products, from snacks and coffee to pet food and premium beverages. Their ability to stand tall on shelves, offer excellent printability, provide resealability, and utilize material efficiently has made them a powerhouse. Yet, a counter-trend is gaining significant traction: the push towards ultra-simplified Single Layer Bags. This dynamic – the sophisticated multi-layer pouch versus the minimalist bag – is reshaping strategies across the industry.

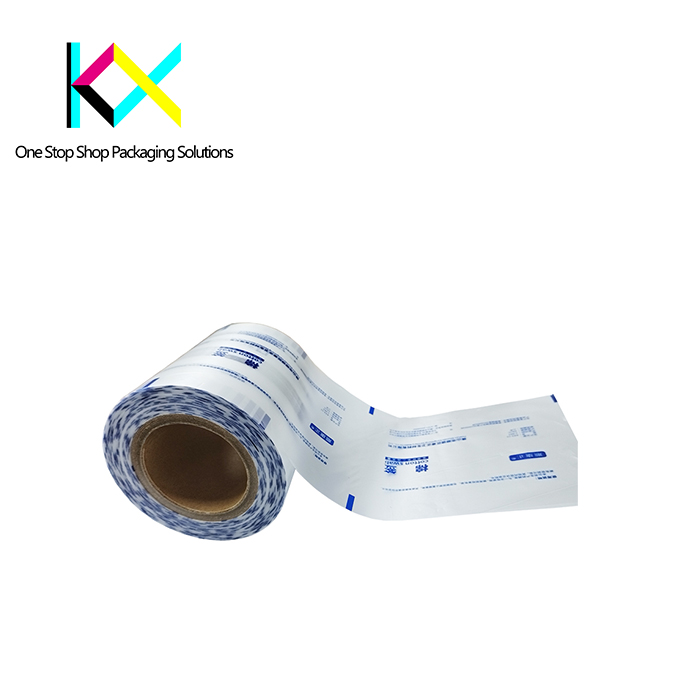

The Silent Engine Driving Smarter Roll Film Packaging

The relentless pursuit of efficiency, performance, and responsibility is reshaping the flexible packaging landscape. At the forefront of this evolution, Dry Lamination is emerging not merely as an alternative process, but as a strategic enabler for the modern era of Roll Film Packaging. This technology, moving beyond niche applications, is proving fundamental in meeting escalating demands for faster production, reduced waste, and enhanced product integrity across countless consumer goods.

The Tangible Revolution Reshaping Flexible Packaging

The global flexible packaging industry stands at a pivotal crossroads, driven by an undeniable mandate: the urgent transition to Sustainable Packaging. No longer a niche concern or mere marketing buzzword, genuine sustainability has become a core operational and strategic imperative. Consumers demand it, regulators enforce it, and the planet desperately needs it. At the heart of this transformation lies a confluence of innovative technologies and shifting priorities, fundamentally altering how packaging is conceived, produced, and disposed of.

How High-Temperature Sterilization Packaging Secures the Future of Food

The global demand for safe, convenient, and shelf-stable food has never been greater, placing immense pressure and opportunity on the Food Packaging sector. At the heart of delivering truly safe, long-life products lies a critical, demanding process: high-temperature sterilization. Food Packaging designed for this rigorous environment isn’t merely a container; it’s a sophisticated life-preservation system, ensuring products are free from harmful pathogens and spoilage organisms. As consumer preferences shift towards cleaner labels, diverse global cuisines, and sustainable solutions, the technologies underpinning High-Temperature Sterilization Packaging are undergoing a significant evolution. This article explores the cutting-edge innovations enabling packaging to withstand extreme thermal processing while meeting modern demands for performance, safety, and environmental responsibility, fundamentally reshaping how we protect and deliver sterilized food to consumers worldwide.

How Foil Bags Evolve as the Gold Standard in Barrier Packaging

In an era demanding peak product protection and extended shelf life, Foil Bags remain an indispensable powerhouse within the protective packaging landscape. These sophisticated structures, leveraging the unparalleled barrier properties of aluminum foil, continue to set the benchmark for safeguarding sensitive contents against oxygen, moisture, light, and contaminants. While sustainability pressures drive innovation across flexible packaging, the unique performance characteristics of Foil Bags ensure their enduring relevance, particularly for high-value, long-shelf-life, or critically sensitive products. Far from being stagnant, the technology behind these bags is undergoing a quiet revolution, integrating new materials, smarter designs, and enhanced sustainability features to meet modern demands without compromising their core protective function. This evolution reaffirms the Foil Bag as a sophisticated, evolving solution within the broader realm of high-performance Barrier Packaging.

How Next-Gen Flexible Films are Redefining Eco-friendly Packaging

he global packaging industry stands at an inflection point, pressured by environmental imperatives and shifting consumer consciousness. At the heart of this transformation lies the urgent pursuit of truly Eco-friendly Packaging. For decades, Flexible Film Packaging – encompassing pouches, bags, wraps, and laminates – has dominated sectors from food and beverage to pharmaceuticals and e-commerce, prized for its lightweight nature, superior barrier properties, and cost-effectiveness. However, its reliance on complex, often unrecyclable multi-material structures and fossil-fuel origins has cast a long environmental shadow. Today, the dynamic is shifting dramatically. Driven by regulatory mandates, corporate sustainability goals, and genuine technological leaps, the sector is experiencing a renaissance. We are witnessing the emergence of next-generation flexible films that no longer force a choice between functionality and planetary responsibility. This evolution moves beyond mere “greenwashing” to deliver tangible, scalable solutions where high performance and environmental stewardship are inextricably linked, fundamentally reshaping what Eco-friendly Packaging means for flexible formats.

How PLA Packaging is Reinventing Flexible Solutions

The soft packaging landscape is undergoing a seismic shift, driven by environmental urgency and technological innovation. At the forefront of this transformation stands PLA Packaging (Polylactic Acid), emerging from its niche origins to challenge conventional materials with its compelling bio-based credentials. Derived annually renewable resources like corn starch or sugarcane, PLA offers a fundamentally different carbon story than fossil-fuel plastics. Yet, its journey into mainstream flexible packaging hinges not just on its green origins, but critically on overcoming performance hurdles – particularly in achieving reliable, high-integrity seals essential for product protection and shelf life. This is where advancements in Heat Seal Packaging technologies become pivotal, acting as the crucial bridge that unlocks PLA’s potential across demanding applications. The synergy between evolving biopolymer formulations and sophisticated thermal bonding techniques is reshaping what’s possible for planet-conscious packaging, moving beyond theory into tangible, commercially viable solutions that meet stringent industry demands for functionality, efficiency, and sustainability.

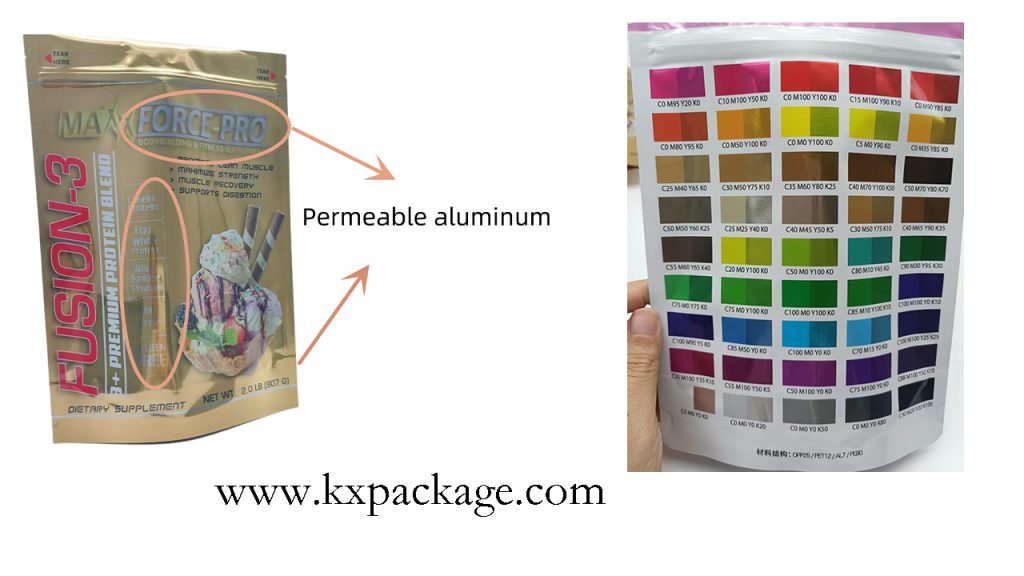

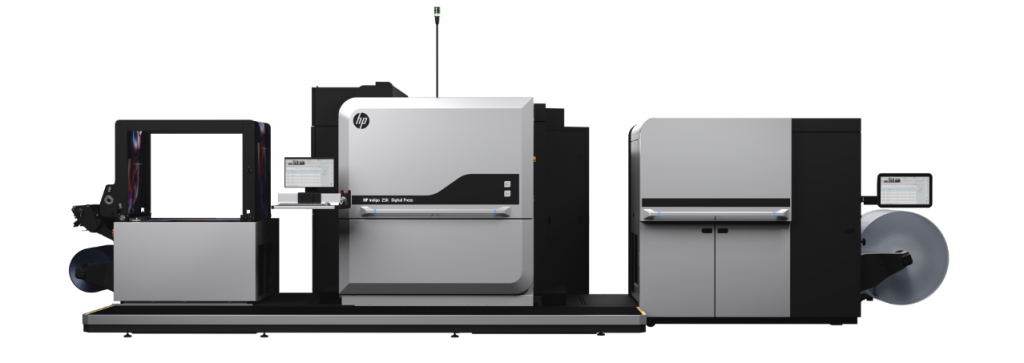

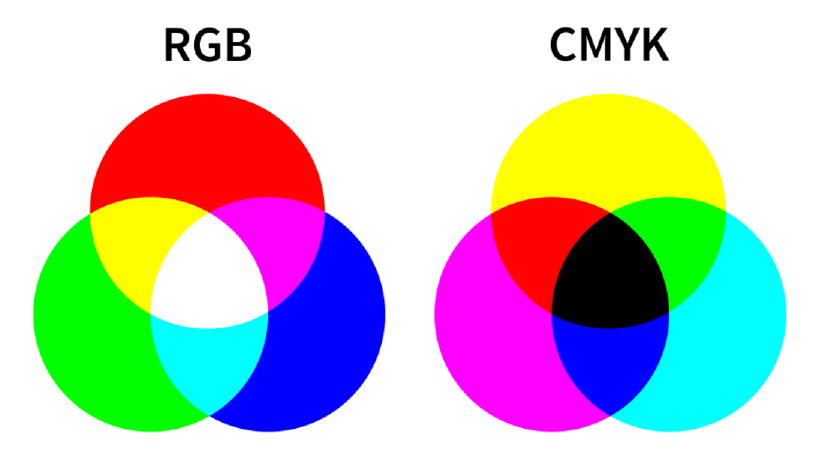

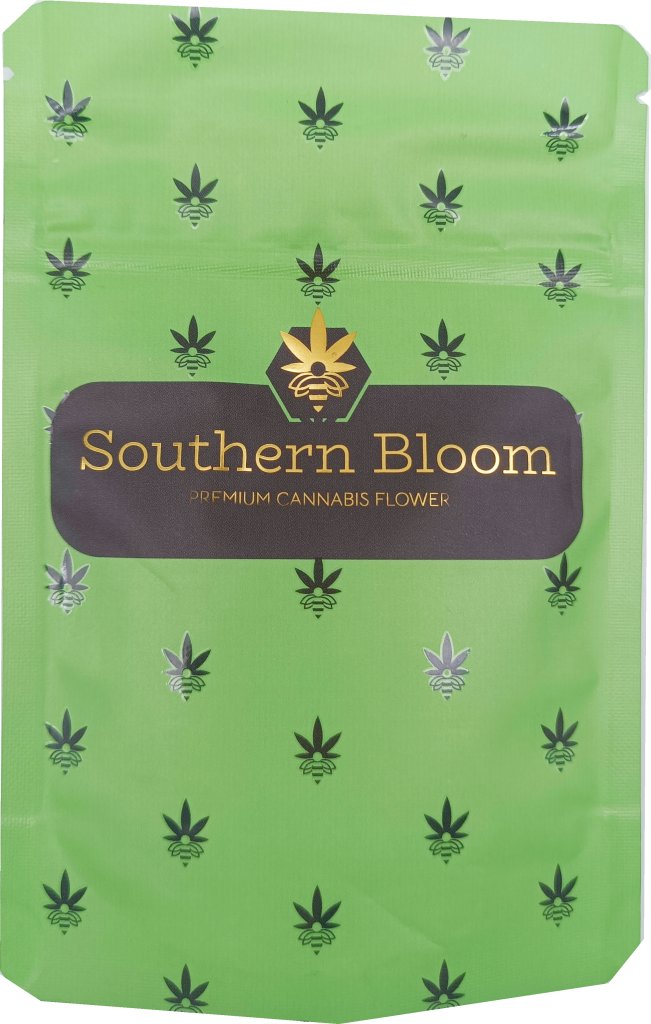

How Composite Packaging Bags Drive Modern Brand Value with Digital Precision

The world of flexible packaging hums with innovation, yet few components are as fundamentally crucial yet often overlooked as the Composite Packaging Bag. These sophisticated structures, meticulously engineered from layers of diverse materials, form the protective heart of countless products lining our shelves – from gourmet coffee and premium pet food to pharmaceuticals and industrial chemicals. Far from simple containers, they represent a pinnacle of material science, balancing critical barriers against moisture, oxygen, light, and contaminants with demands for lightweight efficiency, durability, and increasingly, stunning visual appeal. It is precisely within this realm of high-performance protection that Digital Printing Packaging emerges as a transformative force, injecting unprecedented flexibility, speed, and creative potential into the production of these essential vessels. Together, they are reshaping brand strategies and consumer experiences in the dynamic soft packaging landscape.

Plastic Packaging Transformed: The Biodegradable Breakthrough Reshaping Flexible Solutions

The Sustainability Tipping Point

The plastic packaging industry has reached a critical juncture where environmental imperatives converge with technological possibility. As global plastic waste surpasses 400 million tons annually, traditional flexible films face unprecedented scrutiny. Regulatory tsunamis—from Canada’s Single-Use Plastics Ban to India’s Extended Producer Responsibility framework—have accelerated corporate migration toward biodegradable plastics. Major brands now allocate 15-25% of R&D budgets to sustainable material development, signaling irreversible transformation.

How Medicine Pouch Packaging Is Redefining Pharmaceutical Protection

In the high-stakes pharmaceutical industry, medicine pouch packaging has evolved from passive containment to an intelligent life-preservation system. These precision-engineered solutions now integrate nano-scale barrier technology, real-time monitoring, and circular design principles to combat critical challenges: 35% of drug efficacy loss occurs during transit (WHO), while counterfeit pharmaceuticals represent a $200B global threat (Interpol). Simultaneously, breakthroughs in flexible packaging are transforming how sensitive therapeutics navigate global supply chains while meeting escalating sustainability demands.

How Medical Device Packaging Pouches and Eco Friendly Bakery Bags Are Redefining Packaging Excellence

In today’s hyper-specialized packaging landscape, medical device packaging pouches have evolved into precision-engineered life guardians – where nano-scale barriers and smart monitoring systems protect $500B worth of critical healthcare equipment. Simultaneously, the humble eco friendly bakery bag is undergoing a sustainability revolution, transforming from basic pastry carrier to compostable freshness ecosystem. This convergence of mission-critical protection and consumer-facing sustainability reflects industry-wide transformation: 47% of medical recalls originate from packaging failures (FDA), while 68% of consumers abandon brands over poor eco-practices (IBM).

How Medical Packaging Pouches Are Revolutionizing Device Safety & Compliance

In the high-stakes realm of healthcare, medical packaging pouches have evolved from passive containers to active protective systems—becoming as critical as the devices they safeguard. These precision-engineered barriers now integrate nano-scale material science, real-time monitoring, and circular sustainability to address alarming industry data: 47% of medical device recalls originate from packaging failures (FDA, 2023). Simultaneously, advancements in medical device pouches are redefining sterilization assurance across global supply chains, where a single compromised seal can jeopardize patient safety.

How Clear Film Roll Innovations Are Transforming Product Visibility & Protection

In today’s hyper-competitive retail landscape, clear film roll technology has evolved from basic packaging material to a sophisticated optical engineering solution – merging crystal-clear product visibility with unprecedented technical capabilities. Simultaneously, white paper packaging bag designs are experiencing a renaissance, transitioning from commodity carriers to premium sustainable vessels that communicate brand values through minimalist elegance. This dual evolution responds to converging market demands: 78% of consumers prioritize product visibility before purchase (McKinsey 2023), while 65% associate matte white surfaces with premium quality (Packaging Digest). As global e-commerce grows at 17% annually and sustainability regulations tighten, these materials are becoming strategic assets for brands navigating the new retail reality.

The Precision Frontier: How Medical Device Packaging Innovations Are Safeguarding Global Health

In the high-stakes world of healthcare technology, medical device packaging has evolved from passive container to active protective system – becoming as critical as the devices themselves. These sophisticated barrier solutions now integrate material science, traceability technology, and sustainability imperatives to meet unprecedented challenges: 47% of device recalls stem from packaging failures (FDA, 2023). Simultaneously, advancements in printed film roll technologies are revolutionizing how we communicate vital information while maintaining sterile integrity across global supply chains.

The Reheating Revolution: How Toast Paper Bag Innovations Are Redefining Convenience Packaging

In the high-stakes arena of food preservation and reheating technology, the humble toast paper bag has undergone a quantum leap – evolving from simple bakery carrier to engineered freshness system. These sophisticated solutions now integrate thermal regulation, sustainable materials, and intelligent design to solve the universal challenge of reviving baked goods without sacrificing quality. While aluminum foil roll products continue to dominate high-barrier applications, a new generation of paper-based innovations is rewriting the rules of convenience packaging across retail, food service, and consumer kitchens.

The Freshness Frontier: How Bread Packaging Pouch Innovations Are Transforming Bakery Economics

In today’s hyper-competitive bakery landscape, the bread packaging pouch has evolved from simple container to strategic freshness-preservation system. These sophisticated solutions now integrate material science, sustainability imperatives, and consumer psychology to combat the $12B global food waste crisis. Parallel advancements in bakery paper bags signal a sector-wide reimagining of how we protect, present, and preserve baked goods – with the sustainable packaging market projected to reach $413B by 2027 (Smithers).

The Fresh Frontier: How Biodegradable Paper Pouch Innovations Are Reshaking Food Packaging

In the urgent race against plastic pollution, biodegradable paper pouch solutions have emerged as the vanguard of sustainable packaging – combining advanced material science with circular design principles. These revolutionary containers now deliver performance once exclusive to plastics while offering genuine end-of-life solutions. Parallel innovations in bread packaging paper bags signal a sector-wide transformation, with the global edible packaging market projected to reach $2.7 billion by 2028 (Grand View Research), driven by regulatory pressure and consumer demand for plastic-free solutions.

The Sealed Revolution: How Kraft Paper Heat Seal Bags Transform Sustainable Packaging

In the urgent race toward circular packaging, kraft paper heat seal bags have emerged as the unexpected frontrunner—blending heritage materials with cutting-edge sealing science to challenge plastic dominance. These sophisticated solutions now deliver performance parity with conventional laminates while offering genuine end-of-life solutions. Parallel innovations in kraft paper packaging bags signal industry-wide disruption, with global markets projected to reach $486B by 2027 (Smithers 2024) as brands scramble to meet both consumer expectations and tightening regulations like the EU Packaging Regulation (PPWR).

The Renaissance of Natural Packaging: How Kraft Paper Pouch Packaging is Redefining Sustainable Solutions

In today’s eco-conscious marketplace, kraft paper pouch packaging has emerged as a transformative force, blending heritage materials with cutting-edge innovation. Once relegated to basic commodity bags, these solutions now challenge conventional plastic packaging through technological breakthroughs that enhance functionality while honoring environmental responsibility. Parallel to this evolution, kraft paper food bags have transcended their utilitarian origins to become sophisticated brand assets, reflecting industry-wide shifts toward circular economies and carbon neutrality. This revolution responds to urgent consumer demands: 68% of global shoppers now actively avoid plastic packaging (McKinsey, 2023), creating unprecedented opportunities for kraft-based solutions.

The Future of Sustainable Packaging: How Zipper Paper Pouches Are Revolutionizing Product Storage

In today’s eco-conscious market, zipper paper pouches have emerged as a game-changing solution that combines functionality with environmental responsibility. These innovative packages represent a significant evolution from traditional plastic alternatives, offering brands an opportunity to meet consumer demand for sustainable options without compromising convenience. While kraft paper cookie bags have long been the standard for artisanal bakeries and premium snacks, new technological advancements are transforming them into sophisticated packaging solutions suitable for a wide range of products. This packaging revolution reflects broader industry trends toward circular economy principles, reduced carbon footprints, and smarter material usage across retail and e-commerce sectors.

The Sustainable Packaging Revolution: How Resealable Paper Pouches Are Redefining Eco-Friendly Solutions

In today’s environmentally conscious market, resealable paper pouches have emerged as a game-changing solution that combines sustainability with practical functionality. These innovative packages represent a significant leap forward from traditional plastic alternatives, offering brands an opportunity to meet consumer demand for eco-friendly options without sacrificing convenience. While resealable brown paper bags have long been associated with basic dry goods storage, new technological advancements are transforming them into sophisticated packaging solutions suitable for a wide range of products. This evolution reflects broader industry trends toward circular economy principles, reduced carbon footprints, and smarter material usage.

The Pour-Fection Revolution: How Spout Packaging Pouches Are Changing Liquid Logistics

In the dynamic world of flexible packaging, the spout packaging pouch has emerged as an unsung hero, quietly revolutionizing how we store, transport, and dispense everything from premium olive oils to industrial chemicals. These innovative containers combine the convenience of rigid bottles with the sustainability of flexible films, creating new possibilities across multiple industries. Meanwhile, the humble resealable kraft paper bags is undergoing its own renaissance, evolving from simple dry goods carriers to sophisticated packaging solutions that balance eco-conscious materials with modern functionality. This dual evolution reflects broader industry shifts toward sustainable convenience and precision dispensing.

The Sustainable Shift: How Kraft Zipper Pouches Are Redefining Eco-Conscious Packaging

In an era where environmental responsibility meets consumer convenience, the kraft zipper pouch has emerged as an unlikely hero of sustainable packaging. These unassuming yet sophisticated containers represent a fundamental rethinking of how we balance functionality with ecological impact. While traditional mylar stand up pouches continue to dominate certain market segments with their superior barrier properties, a new generation of kraft-based solutions is challenging the status quo through material innovation and design ingenuity. This evolution reflects broader industry trends toward circular economies, carbon footprint reduction, and consumer demand for authentically “green” packaging options.

The Packaging Revolution: How Custom Printed Stand Up Pouches Are Transforming Brand Experiences

The modern custom printed stand up pouch represents far more than a container—it’s a powerful brand ambassador, a sustainability statement, and a technological marvel all in one. As consumer expectations evolve and environmental regulations tighten, these versatile packaging solutions are undergoing remarkable innovations, particularly in rotogravure printing pouch production. The industry is witnessing five fundamental shifts that are redefining what flexible packaging can achieve.

The Print Revolution: How Flexo Printed Pouches Are Redefining Packaging Excellence

The packaging industry is undergoing a quiet transformation, driven by advancements in printing technology that balance aesthetics, sustainability, and efficiency. At the forefront of this evolution are flexo printed pouches, which combine high-quality graphics with cost-effective production. While traditional rotogravure printed bags have long dominated premium markets, flexography is closing the gap with innovations in precision, speed, and eco-friendliness. This shift is reshaping brand strategies, supply chain dynamics, and consumer perceptions in the flexible packaging space.

Chromatic Cravings: How Cookie Pouch Packaging Revolutionizes Sweet Success

The battle for consumer attention in the cookie aisle begins with a tactile and visual handshake – the cookie pouch packaging that promises delight before the first bite. In today’s hyper-competitive market, this humble container has evolved into a strategic asset where vibrant colored stand up pouches merge neuroscience with material science. The convergence of sensory marketing, sustainability imperatives, and e-commerce logistics has transformed how brands leverage packaging to drive emotional connections and operational efficiency.

The Silent Guardians: How Modern Seed Packaging Pouch Innovations Are Cultivating Industry Change

In the intricate dance between nature and technology, the humble seed packaging pouch has emerged as an unsung hero of agricultural innovation. No longer mere containers, these specialized vessels now balance critical preservation science with sustainability imperatives and consumer engagement strategies. The evolution toward sophisticated seeds stand up pouches represents a fundamental shift in how breeders, growers, and retailers approach seed viability, traceability, and market presentation. This transformation responds to urgent global challenges: biodiversity preservation, supply chain resilience, and the growing demand for transparent food systems.

The Silent Shift: How Food Stand Up Bag Innovations Are Redefining Consumer Connections

The unassuming food stand up bag has become the epicenter of a packaging revolution. Gone are the days when functionality alone dictated design; today’s consumers demand multisensory experiences wrapped in environmental responsibility. At the forefront of this transformation stands the matte stand up pouch – a tactile marvel merging premium aesthetics with groundbreaking engineering. This evolution responds to three seismic shifts: the neuroscience of purchasing decisions, urgent sustainability mandates, and the brutal realities of e-commerce logistics. What begins as a simple container has morphed into a brand’s most potent touchpoint.

Mylar Aluminum Foil Bags: The Science of Sweet Preservation

The mylar aluminum foil bag has emerged as the gold standard in protecting sensory perfection. Where conventional candy pouch packaging often surrenders to humidity and oxidation, these engineered marvels deploy space-grade materials to shield delicate flavors and textures from factory to fingertips.

Resealable Mylar Bags: Engineering the Future of Premium Protection

The resealable mylar bag has undergone a quantum leap – evolving from basic storage to an intelligent preservation ecosystem. Where conventional zip pouch food packaging offered elementary containment, today’s solutions integrate space-grade materials, circular economy principles, and digital intelligence to defend premium contents against time, temperature, and transit.

The Artistry of Freshness: How Custom Made Coffee Bags Elevate Specialty Brews

The custom made coffee bag has become the canvas for specialty roasters’ most critical preservation artistry. Where generic aluminum foil packaging bags once dominated, today’s engineered solutions blend precision barriers, sustainable materials, and brand storytelling to protect delicate volatile compounds from roastery to ritual. This evolution answers third-wave coffee’s non-negotiables: uncompromised freshness and distinctive identity.

The Unseen Evolution: How Packaging Doypack Designs Are Redefining Tea Preservation

The packaging doypack has emerged as the silent guardian of premium tea experiences worldwide. Where traditional tea plastic pouch designs often compromised freshness for convenience, today’s engineered solutions blend material science, sustainability, and sensory preservation to protect delicate leaves from plantation to pot. This revolution responds to discerning tea drinkers demanding both luxury and eco-consciousness in every steep.

The Doypack Stand Up Pouch: Engineering the Future of Functional Packaging

The unassuming doypack stand up pouch has become the Swiss Army knife of modern packaging – a format quietly revolutionizing retail, e-commerce, and sustainability strategies. No longer just a container, today’s advanced iterations combine material science, digital technology, and structural innovation to solve problems traditional stand up plastic bags never could. As consumer goods fragment into niche categories and regulations tighten, this self-supporting hero is rising to meet unprecedented challenges.

From Plastic to Planet: The Evolution of Cat Food Packaging Bags

The rustle of opening a cat food packaging bag remains an enduring ritual in households worldwide. Yet beneath this familiar sound, a material revolution is transforming soft packaging. Driven by eco-conscious pet owners and regulatory shifts, manufacturers are reengineering these essential containers – with biodegradable packaging bags emerging as the frontier solution. This transition represents more than sustainability trends; it signals fundamental recalibration of packaging priorities across the industry.

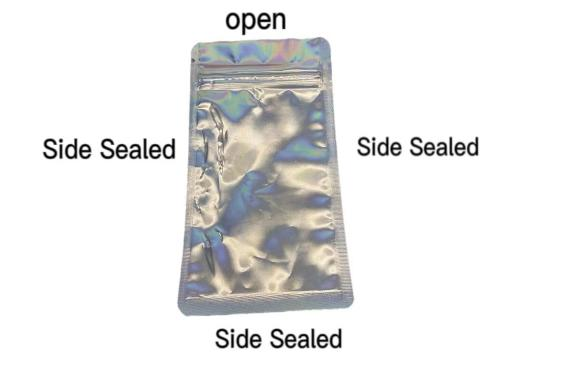

Flat Bottom Zipper Bag: Where Shelf Presence Meets Sustainable Innovation

In the competitive landscape of flexible packaging, the flat bottom zipper bag has emerged as a retail powerhouse – combining freestanding stability with eco-conscious engineering. These self-supporting pouches are redefining product presentation across premium markets while driving unexpected synergies with industrial-grade three side seal pouches. As e-commerce surges and circular economy mandates tighten, both formats are converging to solve the dual challenge of brand impact and planetary responsibility.

Three Side Seal Bag: The Unsung Efficiency Engine Reshaping Modern Packaging

In the high-speed world of flexible packaging, the three side seal bag has emerged as a silent powerhouse – driving unprecedented efficiency while pioneering sustainability. These deceptively simple flat pouches are transforming industries from gourmet coffee to automotive lubricants, proving that minimalist design can maximize impact. As circular economy mandates accelerate, innovations in plastic packaging pouch technology are converging to redefine how products are protected, shipped, and reborn.

Stand Up Zipper Bag: Where Premium Preservation Meets Modern Convenience

In the high-stakes arena of flexible packaging, the stand up zipper bag has evolved from a simple storage solution to a sophisticated preservation system. These vertically stable, resealable powerhouses now dominate premium markets—from craft coffee to boutique skincare—blending unmatched functionality with cutting-edge material science. As sustainability demands intensify, innovations like mylar ziplock bag hybrids are redefining freshness, proving that luxury and eco-consciousness can coexist in perfect harmony.

Eco Friendly Stand Up Pouch: The Vanguard of Plastic Packaging’s Sustainable Transformation

In an era where sustainability intersects with consumer demand, the eco friendly stand up pouch has emerged as a catalyst for change across the flexible packaging landscape. These vertically stable solutions are redefining industry standards, challenging traditional plastic packaging bag conventions, and proving that environmental responsibility need not compromise functionality or shelf appeal. As global regulations tighten and conscious consumers multiply, this evolution marks a pivotal shift toward circularity.

Gusset Packaging Bag: The Unsung Hero of Modern Flexible Packaging Efficiency

In the dynamic world of flexible packaging, the gusset packaging bag has emerged as a quiet powerhouse, delivering unparalleled functionality across industries from gourmet coffee to industrial chemicals. These versatile bags, characterized by their expandable side panels, are undergoing a sustainability revolution while maintaining their core advantage: space-efficient storage that protects premium contents. As e-commerce grows and environmental regulations tighten, innovations in side gusset plastic bags are proving that smart design can reduce waste without compromising performance.

Plastic Spout Pouch: Precision Meets Sustainability in Modern Liquid Packaging

In the quest for packaging that balances functionality with environmental responsibility, the plastic spout pouch has emerged as an unexpected hero. These innovative solutions are redefining liquid dispensing across industries—from food and beverage to automotive chemicals—while driving material science breakthroughs that ripple into unexpected territories like vacuum packaging bags. As circular economy mandates accelerate, these unassuming pouches are proving that convenience and sustainability can flow from the same spout.

3 Side Seal Flat Pouch: The Unsung Efficiency Engine Reshaping Modern Packaging

In today’s hyper-competitive flexible packaging landscape, the 3 side seal flat pouch has emerged as a silent powerhouse – driving cost efficiency, sustainability, and surprising innovation. While flashier formats dominate headlines, this unassuming design is quietly revolutionizing liquid packaging through unexpected partnerships with tap pouch technologies. As brands face mounting pressure to reduce waste and optimize logistics, this overlooked hero is stepping into the spotlight.

Liquid Stand Up Pouch: The Silent Revolution Reshaping Beverage Sustainability

In the dynamic beverage packaging landscape, the liquid stand up pouch has emerged as a game-changing fusion of functionality and eco-innovation. These space-efficient, vertically stable pouches are rapidly displacing rigid containers, leveraging breakthroughs pioneered by beverage spout pouch technologies to slash waste while enhancing consumer convenience. As global pressure mounts to reduce single-use plastics, this packaging format is becoming the linchpin of a circular beverage economy.

Shampoo Refill Pouch Innovations: How Liquid Packaging Is Driving the Circular Beauty Revolution

The personal care industry’s sustainability transformation hinges on a deceptively simple solution: the shampoo refill pouch. These lightweight, flexible packs are disrupting traditional bottle-dominated markets, reducing plastic waste by up to 70% while borrowing material science breakthroughs from an unlikely ally—juice pouch packaging. As global refillable beauty markets surge toward $36B by 2027, these unassuming pouches are becoming linchpins in the zero-waste economy.

Spouted Liquid Stand Up Pouches: Revolutionizing Sustainable Juice Packaging

In today’s rapidly evolving beverage landscape, spouted liquid stand up pouches represent a transformative leap in packaging innovation, merging consumer convenience with environmental stewardship. As juice brands navigate growing pressure to reduce plastic waste and meet stringent regulations, these advanced pouches are redefining juice packaging pouch standards—offering unprecedented functionality while slashing ecological footprints. The global juice market’s projected growth to $154 billion by 2027 underscores the urgency for solutions that balance shelf appeal, freshness, and planetary responsibility.

Plastic Pouch Liquid Packaging: Innovating the Future of Sustainable and Smart Solutions

In the dynamic world of flexible packaging, plastic pouch liquid packaging is undergoing a transformative evolution, driven by sustainability mandates and consumer demand for convenience. Once criticized for its environmental footprint, this versatile format is now embracing cutting-edge materials, intelligent designs, and advanced printing technologies like printed spout pouches to reduce waste and enhance user experience. As industries from beverages to home care seek greener alternatives, the humble plastic pouch is proving its adaptability in a circular economy.

Eco Friendly Spout Pouches: Leading the Charge in Sustainable Liquid Packaging

In an era where environmental accountability shapes consumer choices, eco friendly spout pouches are emerging as a transformative force in the liquid packaging industry. These innovative solutions, designed to minimize waste without compromising functionality, are redefining how beverages, sauces, and personal care products are stored and dispensed. As global demand for sustainable alternatives surges, advancements like biodegradable spout pouch designs and compostable materials are positioning these pouches at the forefront of the circular economy.

Juice Spout Pouches: The Liquid Packaging Revolution Balancing Convenience and Sustainability

In the rapidly evolving beverage industry, juice spout pouches are emerging as a transformative solution, merging user-friendly design with eco-conscious innovation. These pouches, featuring precision-fit spouts and lightweight structures, are redefining how liquids—from cold-pressed juices to plant-based milks—are packaged, stored, and consumed. As brands face mounting pressure to reduce plastic waste and meet stringent regulations, advancements in liquid packaging bags are proving that functionality and environmental stewardship can coexist.

Spouted Stand Up Pouches: Redefining Convenience and Sustainability in Liquid Packaging

In the fast-paced world of liquid packaging, spouted stand up pouches are emerging as a game-changer, blending user-friendly design with eco-conscious innovation. These pouches, equipped with precision-fit spouts and space-efficient structures, are revolutionizing industries from baby food to plant-based beverages. As brands grapple with sustainability mandates and shifting consumer preferences, advancements like recyclable spout pouches are proving that functionality and environmental responsibility can flow seamlessly together.

Kraft Paper Tea Bags: Weaving Tradition into Tomorrow’s Sustainable Brew

In the serene world of tea, where heritage meets hyper-modernity, kraft paper tea bags are emerging as a symbol of eco-conscious evolution. Once a humble vessel for loose leaves, these unbleached, biodegradable bags are now at the forefront of a packaging revolution, inspiring innovations like compostable tea powder packing pouches that cater to matcha enthusiasts and eco-aware consumers alike. As the global tea market surges toward $81 billion by 2031, brands are steeped in a dual mission: preserving flavor and the planet.

Tea Plastic Pouch: Reinventing Sustainability in Modern Tea Preservation

In the ever-evolving landscape of flexible packaging, the tea plastic pouch is undergoing a transformative makeover, driven by both environmental urgency and consumer demand for convenience. Once criticized for its reliance on single-use plastics, this staple of the tea industry is now embracing innovations like recyclable mono-materials, smart designs, and hybrid structures such as the ziplock stand up pouch. As global tea consumption rises—expected to reach 8.1 million tons by 2026—brands are reimagining how tea is stored, sold, and savored, without compromising the planet.

Hot Tea Packaging Pouch: Innovating Tradition in the Modern Tea Renaissance

In the world of tea, where heritage meets hyper-modernity, the hot tea packaging pouch is undergoing a quiet revolution. Once a simple vessel for loose leaves or sachets, today’s pouches are marrying advanced materials, smart technology, and eco-conscious design to cater to discerning consumers. From compostable films to artisanal tea paper packaging bags, the industry is steeped in innovation—proving that even the oldest beverage can adapt to 21st-century demands.

Eco Friendly Tea Bag Packaging: Brewing a Sustainable Future in Flexible Design

In an era where consumers sip consciously and brands steep in sustainability, eco friendly tea bag packaging has emerged as a catalyst for change in the $81 billion global tea industry. No longer confined to traditional envelopes or plastic-lined boxes, today’s innovations—like compostable materials and space-efficient tea stand up pouches—are redefining how tea is preserved, presented, and planet-approved.

Tea Packaging Pouches: Blending Tradition with Tomorrow’s Sustainability

In the world of tea, where heritage meets modern consumer demands, tea packaging pouches have evolved from mere storage solutions to powerful tools for brand storytelling and environmental stewardship. As the global tea market surges toward $81.6 billion by 2030, driven by health-conscious millennials and Gen Z, the humble pouch is undergoing a quiet revolution. Innovations like compostable films, smart labeling, and hyper-personalized custom tea pouches are redefining how tea is preserved, presented, and perceived.

Biscuit Packaging Pouches: The Sweet Spot of Innovation in Modern Food Preservation

In the dynamic world of flexible packaging, biscuit packaging pouches are emerging as a critical player, balancing aesthetics, functionality, and sustainability. As consumers demand longer shelf life, eco-conscious materials, and personalized branding, innovations like zip lock stand up pouches and custom printed resealable food bags are reshaping how snacks and beverages are packaged. From artisanal cookies to premium tea blends, the industry’s pivot toward smarter, greener solutions is redefining freshness and consumer engagement.

Pet Food Stand Up Pouches: Driving Innovation in Sustainable and Smart Packaging

In the rapidly evolving flexible packaging industry, pet food stand up pouches have emerged as a cornerstone of innovation, merging functionality with eco-conscious design. These pouches, celebrated for their space-efficient structure and consumer appeal, are not only redefining pet nutrition storage but also influencing trends in adjacent sectors like cookies packaging bags and sweet pouch packaging. As brands prioritize sustainability and engagement, advancements such as stand up mylar food bags and hyper-customizable designs are setting new benchmarks for freshness, convenience, and environmental responsibility.

Coffee Stand Up Pouches: Pioneering Sustainability and Smart Design in Modern Packaging

In the evolving landscape of flexible packaging, coffee stand up pouches have emerged as a gold standard, blending functionality with eco-conscious innovation. These pouches, known for their space-efficient design and premium shelf presence, are not only transforming how coffee is stored and sold but also influencing adjacent sectors like pet food and dried goods. As brands prioritize sustainability and consumer engagement, advancements such as food safe mylar bags and custom printed mylar bags are redefining expectations across industries—from dry fruit stand up pouch designs to pet food packaging pouch solutions.

Popcorn Packaging Pouches: The Unsung Innovators in Flexible Packaging’s Sustainability Surge

In the bustling world of snack and pet food packaging, popcorn packaging pouches are quietly driving a revolution. Once a simple vessel for movie-night treats, these pouches now embody the intersection of convenience, sustainability, and cross-industry ingenuity. From resealable dog food bags to snacks packaging pouches for nuts and crisps, the lessons learned from popcorn’s quest for freshness are reshaping how brands approach design, material science, and eco-responsibility.

Three Side Seal Pouches: The Silent Force Behind Modern Packaging Efficiency

In the fast-paced world of flexible packaging, three side seal pouches have become an unsung hero, driving efficiency and sustainability across industries. These versatile pouches, characterized by their clean edges and robust seals, are redefining how products like 250 gram coffee bags and pet food packaging balance practicality with environmental responsibility. As brands navigate shifting consumer expectations and regulatory pressures, innovations such as aluminium foil laminated pouches and fully recyclable dog food bags are reshaping the narrative—proving that even the smallest design choices can yield monumental impact.

Flat Bottom Box Pouches: The Unsung Heroes of Modern Flexible Packaging

In an era where packaging must marry form, function, and sustainability, flat bottom box pouches have emerged as a versatile solution reshaping industries from specialty coffee to pet treats. These hybrid designs blend the structural stability of rigid boxes with the lightweight efficiency of pouches, offering brands a canvas for innovation while addressing modern challenges like eco-consciousness and e-commerce durability. As consumer preferences pivot toward convenience and green practices, the ripple effects of flat bottom box pouches are evident—from printed coffee pouches boasting artisan aesthetics to dog treat packaging bags built to withstand chew-happy pups.

Environmentally Friendly Coffee Bags Lead the Charge in Sustainable Packaging Innovation

The global shift toward sustainability has transformed the packaging landscape, and nowhere is this more evident than in the rise of environmentally friendly coffee bags. These pouches, once a niche offering, are now central to brands’ strategies as consumers demand eco-conscious solutions without compromising freshness or functionality. From compostable films to structural innovations like 1kg stand up pouches, the coffee industry is borrowing insights from unexpected sectors—even banana chips packaging bag designs—to pioneer packaging that’s as green as the beans it holds.

How Dried Fruit Packaging Bags Are Redefining Sustainability in Flexible Packaging

The humble dried fruit packaging bags have quietly emerged as unlikely heroes in the global push for eco-conscious flexible packaging. No longer just a vessel for raisins and apricots, these pouches are driving material innovations that ripple across industries—from chips packaging pouch redesigns to biodegradable coffee bags with valve systems. As brands scramble to meet tightening regulations and consumer demands for greener solutions, the lessons learned from snack packaging are proving invaluable, particularly in reimagining how coffee and other perishables are stored, shipped, and displayed.

Snack Pouch Packaging Inspires a New Era of Coffee Freshness and Functionality

The rise of snack pouch packaging has done more than revolutionize how we store chips and granola—it’s quietly reshaping the coffee industry. By borrowing design principles from these lightweight, resealable pouches, coffee brands are reimagining freshness, sustainability, and user convenience in ways that cater to today’s eco-conscious, on-the-go consumers. From valve sealed coffee bags to innovative quad seal coffee bag structures, the cross-industry exchange of ideas is brewing a packaging revolution.

Revolutionizing Freshness: The Rise of Mylar Coffee Bags in Modern Packaging

In an era where sustainability and functionality collide, mylar coffee bags have emerged as a cornerstone of innovation for the coffee industry. These versatile, foil-lined pouches not only preserve the aromatic essence of coffee beans but also reflect a growing commitment to eco-conscious design. As consumer preferences shift toward convenience and environmental responsibility, packaging solutions like single-serve formats, compostable materials, and resealable systems are redefining how coffee reaches our cups.

Aluminium Zip Lock Pouch & Beyond: Innovations Driving Sustainable and Functional Coffee Packaging

The global coffee packaging industry, valued at $3.7 billion in 2024, is undergoing a seismic shift toward sustainability, smart technology, and consumer-centric design. From aluminium zip lock pouch solutions preserving artisanal freshness to flat bottom coffee pouch designs revolutionizing e-commerce logistics, brands are leveraging cutting-edge innovations to meet regulatory demands and eco-conscious consumer expectations. This article explores how recyclable coffee bags with valve, granola packaging bags, and other key formats are redefining the future of flexible packaging.

Flat Bottom Coffee Bag: Pioneering Sustainability and Functionality in Modern Coffee Packaging

The coffee industry’s relentless pursuit of freshness, convenience, and sustainability has elevated the flat bottom coffee bag to a starring role in packaging innovation. As global coffee consumption exceeds 2.25 billion cups daily, brands are reimagining packaging solutions like compostable coffee pouches, custom coffee bag packaging, aluminum foil stand up bag designs, and single-serve 100g coffee bags to meet evolving consumer and regulatory demands. This article explores how these formats are reshaping the industry while addressing pressing environmental and logistical challenges.

Heat Seal Stand Up Pouches: The Vanguard of Coffee Packaging Innovation

In the dynamic world of coffee packaging, heat seal stand up pouches have emerged as a cornerstone for brands aiming to merge functionality, sustainability, and aesthetic appeal. As the global coffee market surges toward $460 billion by 2026, driven by specialty roasts and eco-conscious consumers, packaging innovations like coffee bean packaging bags, eco friendly coffee bags, custom packaging coffee bags, and personalized coffee packets are redefining industry standards. This article explores how these solutions address modern challenges while capitalizing on emerging trends.

Side Gusset Coffee Bags: Innovating Freshness, Functionality, and Sustainability

In the competitive coffee industry, side gusset coffee bags are emerging as a gold standard for brands seeking to balance practicality, freshness, and eco-conscious design. These uniquely structured bags feature expandable side panels that maximize storage capacity while maintaining a compact footprint—ideal for both retail shelves and e-commerce shipping. As consumer demand for premium, sustainable, and convenient packaging grows, innovations in side gusset coffee bags, 1kg coffee bags, 1 lb coffee bags with valve, smell proof mylar bags, and heat seal coffee bags are redefining how coffee is stored, shipped, and savored.

Paper Coffee Bags: The Sustainable Evolution of Coffee Packaging

The coffee industry’s relentless pursuit of freshness and sustainability has propelled paper coffee bags into the spotlight, merging eco-conscious materials with cutting-edge functionality. As consumers demand packaging that aligns with their environmental values, brands are reimagining traditional solutions—from biodegradable coffee bags that vanish harmlessly to gusseted coffee bags optimizing shelf space. This article explores how these innovations, alongside custom coffee bags with valve and resealable heat seal bags, are reshaping coffee packaging in 2024.

Resealable Coffee Bags: The Intersection of Freshness, Function, and Sustainability

In the $460 billion global coffee industry, resealable coffee bags have evolved from simple storage solutions to sophisticated brand ambassadors. As consumers demand peak freshness, eco-conscious materials, and personalized experiences, the packaging sector is responding with innovations that blend smart technology, structural engineering, and sustainable design. From flat bottom food bags optimizing e-commerce logistics to resealable coffee bags with valve preserving artisanal aromas, the modern coffee pouch is a marvel of multifunctional engineering.

Flat Bottom Box Pouch: The Multifaceted Future of Sustainable and Functional Packaging

The flat bottom box pouch has emerged as a structural marvel in the flexible packaging industry, combining the stability of rigid boxes with the lightweight efficiency of pouches. As e-commerce reshapes retail and sustainability becomes non-negotiable, this hybrid design is redefining how brands approach packaging for products ranging from premium chocolates to specialty coffee. With its rigid base and collapsible sides, the flat bottom box pouch optimizes shelf presence, shipping efficiency, and recyclability—a trifecta of benefits driving its adoption across sectors.

Food Packaging Pouch with Zipper: The Evolution of Convenience in Modern Snacking

In today’s fast-paced, sustainability-driven market, the food packaging pouch with zipper has become a linchpin for brands aiming to balance consumer convenience with environmental responsibility. These resealable marvels are no longer mere storage solutions—they are critical tools for freshness preservation, brand differentiation, and waste reduction. As global snack sales surge toward $1.2 trillion by 2030, innovations in custom plastic zipper pouch designs and smart materials are reshaping how products are packaged, shipped, and experienced.

Personalised Food Bags: The New Frontier in Brand-Consumer Connection

In an era where individuality reigns supreme, personalised food bags are transforming generic products into memorable brand experiences. From artisanal snacks to premium pet treats, custom-printed packaging now serves as a direct line of communication between brands and consumers, driven by advancements in digital printing, smart materials, and eco-conscious innovation. As sustainability regulations tighten and e-commerce reshapes retail, the flexible packaging industry is responding with solutions that blend personalization, functionality, and environmental responsibility.

Protein Powder Pouches: Revolutionizing Supplement Packaging in the Fitness Era

The global protein supplement market, projected to reach $40 billion by 2028, is driving unprecedented innovation in functional packaging. At the forefront of this evolution are protein powder pouches, which have transitioned from basic storage solutions to sophisticated tools for brand differentiation and sustainability. These pouches now address critical consumer demands—freshness preservation, eco-conscious design, and user convenience—while aligning with stringent industry regulations.

Innovative Printed Coffee Bags with Valve: The New Standard in Freshness-Driven Branding

In the competitive world of specialty coffee, printed coffee bags with valve have become non-negotiable for roasters aiming to balance artisanal quality with commercial success. These innovative packages combine precision degassing technology with high-impact branding, addressing two critical consumer demands: peak freshness and visual storytelling. As sustainability regulations tighten and e-commerce reshapes retail, the 2024 packaging landscape rewards brands that merge functional engineering with eco-conscious creativity.

🚀 Whey Protein Pouch Packaging: The Secret to Winning the Fitness Market

In the booming sports nutrition industry, whey protein pouch packaging has become a critical battleground for brand differentiation. With global protein supplement sales projected to exceed $30 billion by 2026, innovative packaging solutions are no longer optional—they’re essential for capturing health-conscious consumers who demand convenience, freshness, and sustainability. Modern whey protein pouch packaging now combines advanced barrier technologies with smart design features, creating a seamless user experience from gym bag to kitchen shelf.

🚀 Stand Up Mylar Food Bags: The Ultimate Fusion of Freshness & Sustainability

In the dynamic world of food packaging, stand up mylar food bags are redefining freshness and functionality. With their superior light-blocking properties and resealable convenience, these innovative bags are becoming the go-to choice for brands prioritizing product longevity and shelf appeal. As consumers demand eco-conscious solutions, manufacturers are now combining Mylar’s protective qualities with recyclable materials—proving that sustainability and performance can coexist.

Custom Printed Food Packaging Bags: Revolutionizing Brand Presentation and Sustainability

In today’s rapidly evolving food industry, custom printed food packaging bags have emerged as a critical differentiator for brands looking to make an impact. These innovative packaging solutions combine cutting-edge printing technology with advanced material science to create packaging that not only protects products but also serves as a powerful marketing tool. As consumer preferences shift toward sustainable and visually appealing options, manufacturers are responding with smarter, more eco-conscious designs.

Innovative Gusset Packaging Bag: The Future of Flexible Packaging SolutionsInnovative Gusset Packaging Bag: The Future of Flexible Packaging Solutions

The gusset packaging bag has emerged as a game-changer in modern product packaging, combining practical functionality with cutting-edge design. As sustainability and convenience become top priorities for global consumers, these versatile pouches are setting new standards across multiple industries. With their expandable sides and sturdy base, gusset bags offer superior storage capacity while maintaining excellent shelf presence – a perfect example of form meeting function in today’s competitive marketplace.

Innovations in Degassing Valve Pouches: Revolutionizing Modern Flexible Packaging

The packaging industry is witnessing a transformative era, with degassing valve pouches leading the charge in preserving product freshness across multiple sectors. From specialty coffee to artisanal snacks, these intelligent pouches are redefining shelf life and consumer satisfaction. Coupled with advancements in candy packaging pouches, hand soap pouches, custom quad seal bags, and digital printed packaging pouches, the market now offers solutions that blend functionality with sustainability.

Digital Printed Coffee Bags: Revolutionizing Specialty Coffee Packaging

In the competitive specialty coffee market, digital printed coffee bags are transforming how roasters present their products while maintaining exceptional quality. This innovative packaging approach, combined with advancements in digital printing on stand up pouches and functional designs like flat bottom zipper bags, offers unprecedented opportunities for brand differentiation and sustainability.

Recyclable Spout Pouches: Pioneering Sustainable Liquid Packaging Solutions

The packaging industry stands at a critical juncture where environmental responsibility meets innovative design. Recyclable spout pouches have emerged as a transformative solution, offering brands an effective way to package liquids while addressing pressing sustainability concerns. Alongside complementary formats like brown kraft paper stand up pouches and eco stand up pouches, these packaging innovations are reshaping product delivery systems across multiple sectors.

Ziplock Standing Pouch: The Smart Choice for Modern Packaging Solutions

In today’s competitive market, the ziplock standing pouch has emerged as a versatile packaging solution that combines convenience with sustainability. Alongside innovative designs like black kraft paper pouches, stand up coffee pouches with valve, and custom kraft pouches, the ziplock standing pouch is redefining product presentation and preservation. These packaging options aren’t just about containing products – they’re about enhancing brand value while meeting evolving consumer demands for functionality and environmental responsibility.

Stand Up Food Pouches: Revolutionizing Convenience and Sustainability in Packaging

In the ever-evolving world of flexible packaging, stand up food pouches have become a cornerstone for brands seeking both functionality and eco-conscious design. Alongside innovations like square bottom pouches, back seal pouches, and sealable paper pouches, stand up food pouches are redefining how products are stored, displayed, and consumed. These solutions are not just about protecting contents; they’re about enhancing user experience while meeting the growing demand for sustainable packaging. Let’s explore how these designs are transforming industries and what makes them a smart choice for forward-thinking brands.

Stand Up Zipper Pouches: The Versatile Solution for Modern Packaging Needs

In the fast-paced world of flexible packaging, stand up zipper pouches have emerged as a go-to solution for brands seeking convenience, functionality, and sustainability. Alongside innovations like dry food packaging bags, compostable kraft pouches, and mylar stand up pouches, these designs are redefining how products are stored, displayed, and consumed. These solutions are not just about protecting contents; they’re about enhancing user experience while meeting the growing demand for eco-friendly options. Let’s explore how these pouches are transforming industries and what makes them a smart choice for forward-thinking brands.

Stand Up Zipper Pouches: The Versatile Solution for Modern Packaging Needs

In the fast-paced world of flexible packaging, stand up zipper pouches have emerged as a go-to solution for brands seeking convenience, functionality, and sustainability. Alongside innovations like dry food packaging bags, compostable kraft pouches, and mylar stand up pouches, stand up zipper pouches are redefining how products are stored, displayed, and consumed. These designs are not just about protecting contents; they’re about enhancing user experience while meeting the growing demand for eco-friendly solutions. Let’s explore how these pouches are transforming industries and what makes them a smart choice for forward-thinking brands.

Recycling Pet Food Pouches: A Sustainable Shift in Flexible Packaging

The global push for sustainability has brought recycling pet food pouches into the spotlight, as brands and consumers alike seek eco-friendly alternatives to traditional packaging. Alongside innovations like redcycle coffee bags, recyclable flexible pouches, and custom standing pouch designs, recycling pet food pouches is redefining how we think about packaging waste. These solutions are not just about reducing environmental impact; they’re about creating a circular economy where materials are reused, not discarded. Let’s explore how these advancements are transforming the packaging landscape and what it takes to make them a reality.

White Kraft Paper Pouch: The Sustainable Star of Modern Flexible Packaging

The packaging industry is undergoing a transformative shift, and the white kraft paper pouch is emerging as a standout solution for brands seeking sustainability without sacrificing functionality. Alongside innovations like flexible plastic bags, pillow pouch packaging, and quad seal pouches, the white kraft paper pouch is redefining how products are stored, protected, and delivered. These solutions are not just about reducing waste; they’re about creating packaging that aligns with both consumer expectations and environmental goals. Let’s explore how these designs are reshaping industries and what makes them a smart choice for forward-thinking brands.

Recyclable Packaging Pouches: The Future of Sustainable Flexible Packaging

The global packaging industry is undergoing a transformative shift, and recyclable packaging pouches are at the forefront of this revolution. As consumers and regulators demand greener alternatives, recyclable packaging pouches—ranging from recyclable cookie bags to white kraft stand up pouches—are setting new standards for functionality and environmental responsibility. These innovations are not just about reducing waste; they’re about reimagining how we store, protect, and deliver products in a way that aligns with planetary health. Let’s explore how recyclable packaging pouches are reshaping industries and what it takes to stay ahead in this rapidly evolving landscape.

Compostable Doypack: Leading the Charge in Sustainable Food Packaging

The global packaging industry is undergoing a transformative shift, and compostable doypack solutions are at the forefront of this revolution. As consumers and regulators demand greener alternatives, compostable doypack designs—alongside biodegradable plastic bags for food packaging and biodegradable kraft stand up pouches—are setting new standards for functionality and environmental responsibility. These innovations are not just about reducing waste; they’re about reimagining how we store, protect, and deliver products in a way that aligns with planetary health. Let’s explore how these eco-friendly solutions are reshaping industries and what it takes to stay ahead in this rapidly evolving landscape.

Sustainable Packaging Bags: Redefining Eco-Friendly Solutions in Flexible Packaging

The global packaging industry is undergoing a transformative shift, and sustainable packaging bags are at the forefront of this revolution. As consumers and regulators demand greener alternatives, sustainable packaging bags—ranging from flat bottom zipper pouches to compostable packaging pouches—are setting new standards for functionality and environmental responsibility. These innovations are not just about reducing waste; they’re about reimagining how we store, protect, and deliver products in a way that aligns with planetary health. Let’s explore how sustainable pouch packaging is reshaping industries and what it takes to stay ahead in this rapidly evolving landscape.

Recyclable Pouch Packaging: The Future of Sustainable Flexible Packaging

The global packaging industry is at a crossroads, and recyclable pouch packaging is leading the charge toward a more sustainable future. As consumers and regulators demand eco-friendly solutions, recyclable pouch packaging has emerged as a game-changer, offering a viable alternative to traditional single-use plastics. From recyclable coffee bags to paper stand up zipper pouches, these innovations are redefining how we think about packaging. But what makes recyclable pouch packaging truly sustainable, and how is it transforming industries? Let’s explore the latest trends, challenges, and breakthroughs in this dynamic space.

Eco Friendly Packaging Pouches: The Sustainable Revolution in Flexible Packaging

The global packaging industry is undergoing a seismic shift, and at the heart of this transformation are eco friendly packaging pouches. These innovative solutions are not just a trend but a necessity, driven by consumer demand for sustainability, stringent regulations, and breakthroughs in material science. From biodegradable plastic pouches to biodegradable zip lock pouches, the market is brimming with options that promise to protect products while preserving the planet. But what makes these pouches truly eco-friendly, and how are they reshaping industries? Let’s dive into the dynamic world of eco friendly packaging pouches and explore their impact, challenges, and future potential.

Eco Friendly Packaging Pouches: Redefining Sustainability in the Flexible Packaging Revolution

The rise of eco friendly packaging pouches marks a pivotal shift in the global fight against plastic pollution, driven by consumer demand, regulatory pressure, and material innovation. As brands scramble to align with circular economy principles, eco friendly packaging pouches—particularly biodegradable variants—are emerging as both a solution and a challenge. From snack bars to premium coffee, these pouches promise to protect products while decomposing harmlessly. But beneath the green veneer lies a complex landscape of scientific breakthroughs, regulatory hurdles, and evolving consumer expectations. Let’s unpack how eco friendly packaging pouches are reshaping industries—and what it takes to avoid greenwashing pitfalls.

Compostable Pouch Packaging: Rewriting the Rules of Sustainable Flexibility

The plastic waste crisis has reached a boiling point, but a quiet revolution is brewing in the flexible packaging sector: compostable pouch packaging is redefining how we store, protect, and dispose of everyday products. No longer confined to niche organic brands, compostable pouch packaging now combines industrial-grade performance with cradle-to-compost circularity. From coffee beans to ready meals, these innovative pouches are challenging the myth that sustainability requires sacrificing functionality. Let’s dissect how compostable pouch packaging bridges ecological responsibility with real-world demands.

Compostable Coffee Bags: Pioneering a Zero-Waste Revolution in Modern Packaging

The global coffee industry is waking up to a bitter reality: traditional plastic packaging contaminates ecosystems long after the last sip. Enter compostable coffee bags—the game-changing solution brewing a sustainable future. As consumers demand eco-conscious options and governments tighten single-use plastic bans, compostable coffee bags are emerging as the gold standard for roasters aiming to blend environmental responsibility with premium brand appeal. But what makes these bags more than just a green marketing gimmick? Let’s explore the science, challenges, and innovations reshaping this niche.

What Are Common Food Packaging Types and Their Ideal Applications? Exploring Modern Solutions in Flexible Packaging

The food packaging industry is undergoing a transformative shift, driven by sustainability mandates, e-commerce growth, and smart technology integration. Understanding common food packaging types and their optimal applications is crucial for brands aiming to balance functionality, cost, and environmental impact. From resealable pouches for snacks to vacuum-sealed films for fresh produce, common food packaging types now incorporate cutting-edge materials and digital innovations to meet evolving consumer and regulatory demands. Let’s unpack the key common food packaging types reshaping the market and their ideal product pairings.

What Are the Standards for Food Packaging Design? Navigating Compliance and Innovation in Modern Flexible Packaging

In the dynamic world of food safety and consumer expectations, food packaging design standards serve as the critical blueprint for creating functional, safe, and sustainable solutions. As global regulations tighten and eco-conscious demand grows, adhering to food packaging design standards while embracing cutting-edge innovations has become a non-negotiable balance for brands and manufacturers. From barrier performance to smart labeling, let’s explore how today’s food packaging design standards are evolving alongside advancements in materials, technology, and circular economy principles.

What Are the Applications of Retort Pouches? Exploring the Versatility of High-Temperature Flexible Packaging