Can Retort Pouches Revolutionize Liquor Packaging? Exploring Next-Gen Solutions in Flexible Packaging

The global flexible packaging industry is undergoing a seismic shift, driven by sustainability mandates and cutting-edge material science. As distilleries seek alternatives to traditional glass bottles and metal cans, an unexpected contender has emerged: retort pouches. Best known for preserving ready-to-eat meals through high-temperature sterilization, these multilayer pouches are now being reimagined for alcoholic beverages – but can they truly meet the exacting standards of liquor packaging?

Breaking the Mold: Why Retort Pouches Merit Attention

Retort packaging, capable of withstanding 121°C sterilization processes, combines aluminum foil, nylon, and food-grade polypropylene into a formidable barrier system. For spirits brands, this technology offers four compelling advantages:

Premium Preservation

Advanced 7-layer structures achieve oxygen transmission rates below 0.5 cc/m²/day – surpassing most glass closures. Japanese sake producers like Hakutsuru have successfully extended shelf life by 40% using nitrogen-flushed retort pouches.Carbon Footprint Reduction

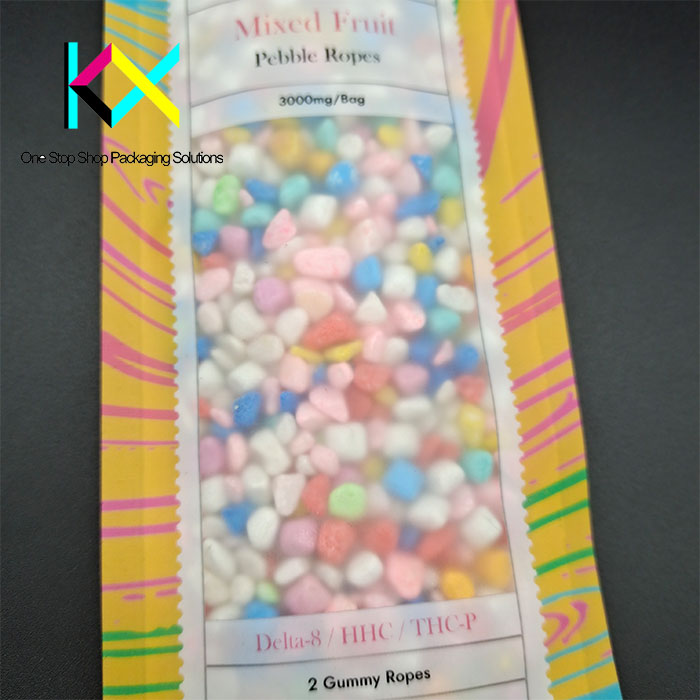

At 85% lighter than glass equivalents, retort pouches slash transportation emissions dramatically. Patrón Tequila’s pilot program reduced packaging weight from 480g (glass) to 28g per 750ml serving, cutting logistics costs by 60%.Design Innovation

Digital printing enables photorealistic branding on curvilinear pouch surfaces. Bacardi’s limited-edition retort-packed rum featured augmented reality labels that came alive when scanned – a feat impossible with conventional bottles.Dosing Convenience

Portion-controlled spouted pouches are gaining traction in airline mini-bars and outdoor recreation markets. Diageo’s 50ml Johnnie Walker pouches reduced breakage incidents by 92% compared to miniature glass bottles.

Material Science Breakthroughs Addressing Historical Limitations

Early adoption attempts faltered due to alcohol interaction with inner layers. Current innovations have overcome these hurdles:

Alcohol-Resistant Films

Companies like Amcor now offer EVOH-free barrier structures using plasma-enhanced SiO₂ coatings, eliminating the “flavor scalping” phenomenon observed in early prototypes.Recyclable Monomaterials

Dow Chemical’s RecycleReady technology creates retort-grade pouches using 94% polyethylene, compatible with existing recycling streams. Absolut Vodka’s trial achieved 96% material recovery rate in Scandinavian facilities.Active Barrier Systems

Mitsubishi Gas Chemical’s oxygen scavenging films combine iron-based compounds with humidity control layers, maintaining optimal conditions for aged whiskeys over 5+ years.

The Sustainability Imperative Driving Adoption

With the EU’s Single-Use Plastics Directive pushing for 30% recycled content in packaging by 2030, distilleries face mounting pressure to innovate. Retort pouches present multiple eco-advantages:

Lifecycle Analysis

A 2023 McKinsey study showed retort-based packaging systems reduce cradle-to-grave emissions by 73% compared to glass/virgin PET combinations.Circular Economy Integration

Chemical recycling pioneers like Loop Industries can now break down used retort pouches into food-grade PET and aluminum components within closed-loop systems.Bio-Based Alternatives

Braskem’s sugarcane-derived polyethylene and Futamura’s cellulose-based barrier films are enabling fully renewable retort solutions. Patagonia Brewing Company’s “Plastic Negative” beer pouches combine these technologies with carbon-negative production methods.

Smart Packaging Convergence

The fusion of retort technology with IoT capabilities is creating unprecedented consumer engagement:

Temperature History Indicators

FreshCode’s color-changing inks help verify proper storage conditions for premium cognacsNFC-Enabled Quality Assurance

ThinFilm’s SpeedTap tags allow consumers to scan packaging for authentication and cocktail recipe suggestionsSelf-Chilling Systems

Phase-change material compartments activated by twisting the pouch neck can chill contents to 4°C in 90 seconds – a game-changer for outdoor enthusiasts

Market Validation and Future Projections

While currently holding just 1.2% of the global spirits packaging market (Smithers 2024 data), retort pouches are growing at 18.7% CAGR. Key developments suggest mainstream adoption:

Regulatory Milestones

The TTB approved retort pouches for US liquor sales in 2023 following extensive migration testingLuxury Brand Endorsement

Hennessy’s limited-edition “Jet Age Reserve” cognac pouches for private aviation clients sold out within 72 hoursEmerging Market Potential

India’s Allied Blenders saw 300% growth in pouch-packaged whisky sales in rural areas where glass recycling infrastructure is limited

Implementation Considerations

Successful transition requires addressing:

-

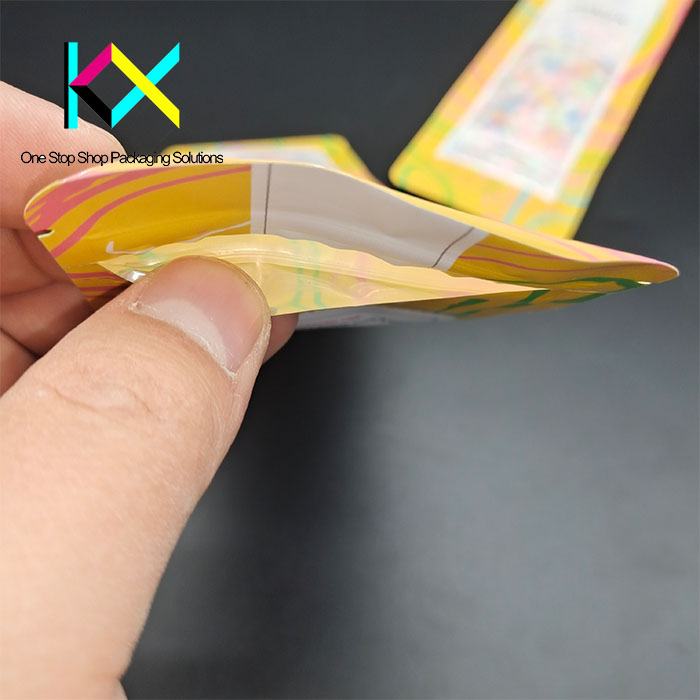

Consumer Perception

Tactile enhancers like embossed textures and weighted bottoms help maintain premium feel -

Fill Technology

Adapting vertical form-fill-seal machines for high-viscosity liquids remains challenging -

Regulatory Compliance

FDA 21 CFR 175.300 standards demand rigorous testing for long-term alcohol contact

As circular economy principles reshape packaging paradigms, retort technology offers spirits producers an unprecedented opportunity to combine environmental stewardship with technical superiority. While not suitable for century-aged rarities, these pouches are poised to dominate the premium ready-to-drink and mainstream liquor segments within this decade. The question is no longer “can they hold liquor,” but rather “how fast can traditional packaging adapt?”

You can visit our website to know more about our flexible packaging pouch: