Can Retort Pouches Withstand Pressure Cooker Heating? Exploring Safety and Innovations in High-Temperature Packaging

The rise of home meal prep and ready-to-eat convenience foods has sparked a critical question among consumers: Can retort pouches—the flexible packaging used for soups, stews, and ready meals—safely go into a pressure cooker? As the global retort packaging market surges toward $6.8 billion by 2027 (Allied Market Research, 2023), understanding the capabilities and limitations of these pouches is essential for both manufacturers and end-users.

What Are Retort Pouches?

Retort pouches are multilayer flexible packages designed to withstand high-temperature sterilization (typically 121°C/250°F). Composed of materials like polyester, aluminum foil, and polypropylene, they’re widely used for shelf-stable foods. However, pressure cookers operate under higher temperatures (up to 135°C/275°F) and pressures (15-20 psi), raising concerns about pouch integrity.

Can Retort Pouches Survive Pressure Cookers?

The answer depends on three key factors:

Material Composition

Standard retort pouches (with aluminum foil barriers) are tested for 121°C sterilization but may fail under prolonged pressure cooking.

Next-gen all-plastic pouches using EVOH or SiO₂ coatings (e.g., Amcor’s AmLite Ultra) can handle up to 130°C, making them borderline suitable for pressure cooking.

Seal Strength

Pressure cookers require heat-sealed seams that withstand at least 3.5 kg/cm². Recent advancements in laser-guided sealing systems, like those from FlexPackAI, have increased seal durability by 40%.Liquid Expansion

The 2023 Journal of Food Engineering warns that rapid pressure changes can cause pouch expansion, risking seal failure. Brands like Nomad Nutrition now integrate pressure-equalizing micro-valves in their camping meal pouches.

Industry Innovations Addressing Pressure Cooking Demands

To meet consumer demand for versatile packaging, manufacturers are reengineering retort pouches:

1. High-Temperature Films

Companies like Mitsubishi Chemical have developed films combining PEN (polyethylene naphthalate) and ceramic-coated barriers, stable up to 140°C. These are now used in premium baby food pouches.

2. Smart Pressure Sensors

Thin, embedded sensors from TempTime Corp. change color if internal pressure exceeds safe limits, providing real-time visual alerts.

3. Recyclable Structures

While traditional aluminum foil pouches aren’t recyclable, new monomaterial solutions like Dow’s RecycleReady™ PP-based pouches maintain pressure cooker compatibility.

4. Hybrid Designs

Sealed Air’s Cryovac® Compass pouches feature reinforced corners and “burst panels” to safely release excess pressure.

Safety Guidelines for Consumers

Check Labels: Look for explicit “pressure cooker safe” certifications like ASTM F1980-21.

Avoid Overfilling: Leave 20% headspace to accommodate liquid expansion.

Low-Acid Foods Only: Pressure cooking low-acid foods (pH >4.6) in pouches risks botulism if heat distribution is uneven.

Case Study: Revolutionizing Home Meal Kits

Meal kit giant HelloFresh recently partnered with ProAmpac to launch pressure cooker-compatible pouches for their “15-Minute Gourmet” line. Using graphene-enhanced films, these pouches reduced cooking time by 25% while withstanding 18 psi pressure.

Sustainability Meets High-Performance

The push for circular economy solutions is reshaping retort pouch design:

Chemical Recycling: Eastman’s molecular recycling technology can now break down used retort pouches into virgin-quality materials.

Bio-Based Films: Futamura’s NatureFlex™ films, derived from wood pulp, offer a compostable alternative for pressure cooker applications.

The Future of Retort Packaging

Emerging trends to watch:

Active Pressure Management: Pouches with shape-memory polymers that adjust to pressure changes.

IoT Integration: QR codes linking to pressure cooker compatibility databases.

Edible Barriers: Whey protein coatings being tested as aluminum foil replacements.

Conclusion

While not all retort pouches are pressure cooker-safe, advancements in material science and smart design are closing the gap. For brands, this represents an opportunity to innovate; for consumers, it’s a call to verify packaging specifications carefully.

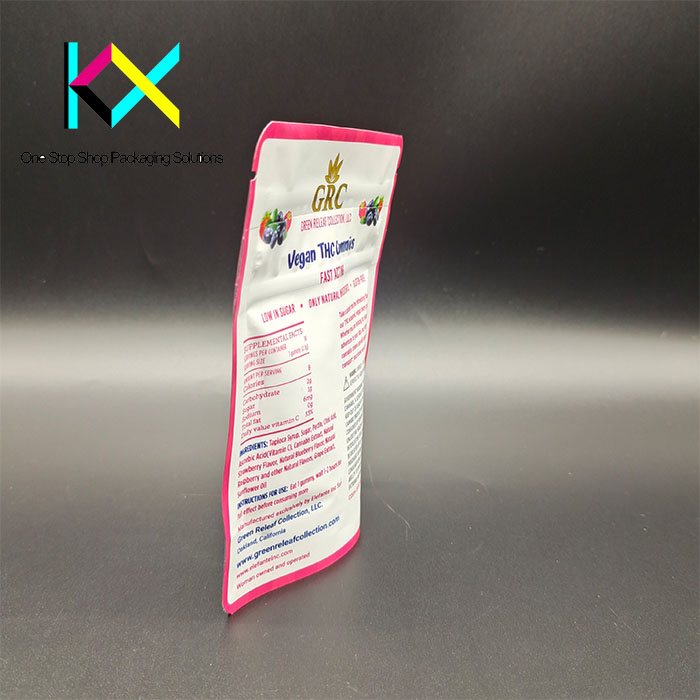

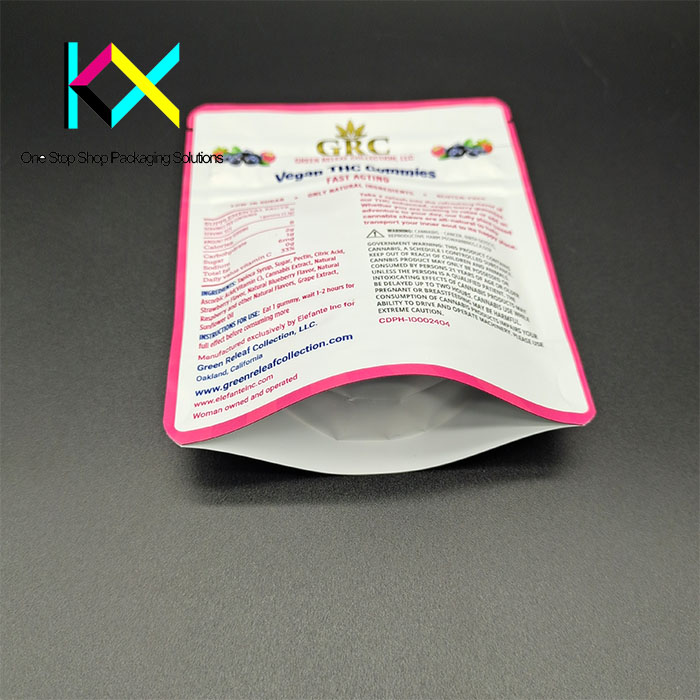

At Kexin Packaging, we’re pioneering next-gen retort solutions that marry safety, sustainability, and pressure-cooker readiness. Let’s redefine what’s possible in high-temperature flexible packaging!

You can visit our website to know more about our flexible packaging pouch: