Flat Bottom Box Pouch: The Multifaceted Future of Sustainable and Functional Packaging

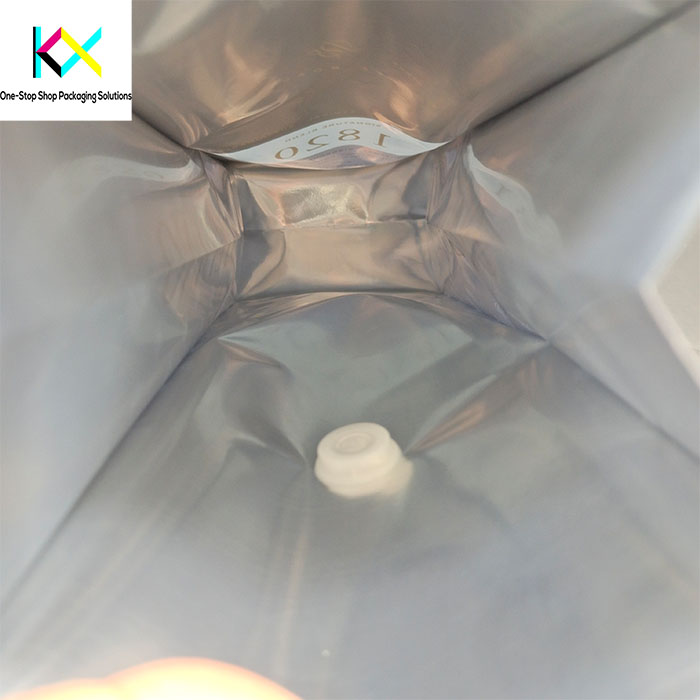

The flat bottom box pouch has emerged as a structural marvel in the flexible packaging industry, combining the stability of rigid boxes with the lightweight efficiency of pouches. As e-commerce reshapes retail and sustainability becomes non-negotiable, this hybrid design is redefining how brands approach packaging for products ranging from premium chocolates to specialty coffee. With its rigid base and collapsible sides, the flat bottom box pouch optimizes shelf presence, shipping efficiency, and recyclability—a trifecta of benefits driving its adoption across sectors.

1. Structural Innovation Meets E-Commerce Demands

The rise of direct-to-consumer sales has made the flat bottom box pouch indispensable. Its unique design addresses critical logistics challenges:

Drop Resistance: Reinforced corners withstand 15-foot tumbles in transit

Space Efficiency: Collapses to 30% of its volume when empty, cutting storage costs

Premium Unboxing: Rigid base mimics luxury box aesthetics at a fraction of the weight

Chocolate brands like CocoaCraft report 40% fewer damaged shipments using flat bottom box pouch designs with integrated cushioning layers. The format’s stability also enables novel applications, such as chocolate powder pouch packaging with built-in measuring scoops—perfect for baking enthusiasts seeking mess-free precision.

2. Barrier Breakthroughs for Sensitive Products

As consumers demand longer shelf lives without preservatives, advanced barrier materials are crucial. Enter smell proof mylar bags and aluminium foil pouch packaging, which now leverage:

Nano-Ceramic Coatings: Replacing traditional aluminum layers while maintaining UV/oxygen barriers

Active Scavengers: Oxygen-absorbing liners extending coffee freshness by 60%

Recyclable Metallization: Silicon oxide coatings enabling curbside recycling of foil pouches

These innovations are critical for products like seasonal chocolate powder pouch editions, where flavor preservation directly impacts brand reputation. MochaBlend’s compostable coffee bags now integrate mylar-like barriers using cellulose-based films—a breakthrough achieving 18-month freshness without aluminum.

3. The Compostable Revolution in Coffee Packaging

With 68% of coffee drinkers prioritizing eco-friendly packaging (NCA 2024), compostable coffee bags are no longer niche. Recent advancements include:

Mycelium Liners: Mushroom-root barriers breaking down in 90 days

Marine-Degradable Valves: Degassing systems safe for ocean disposal

Blockchain Tracking: QR codes verifying compostability certifications

Brands like EarthRoast now use compostable coffee bags with embedded wildflower seeds—plant the pouch to grow pollinator-friendly blooms. This aligns with EU’s Packaging and Packaging Waste Regulation (PPWR), which mandates 65% compostable packaging for beverages by 2025.

4. Smart Features Elevate User Experience

Modern flat bottom box pouch designs integrate technology bridging physical and digital worlds:

AR-Triggered Labels: Scan to reveal brewing tutorials for compostable coffee bags

Smart Zippers: NFC-enabled reseals auto-reordering chocolate powder pouch refills

Temp-Sensitive Inks: Warn if aluminium foil pouch packaging exceeds safe storage heat

Swiss chocolatier LuxeCao saw a 200% social media boost after launching limited-edition smell proof mylar bags with LED-lit holiday motifs—powered by biodegradable battery patches.

5. Regulatory Compliance as a Design Driver

Global legislation is accelerating packaging innovation:

California’s SB54: Bans non-recyclable aluminium foil pouch packaging by 2027

FDA’s Active Packaging Guidelines: Require freshness indicators for chocolate powder pouch products

EU’s Single-Use Plastics Directive: Favors compostable coffee bags over traditional laminates

These policies push brands toward mono-material flat bottom box pouch designs. GreenWrap’s 100% PE structure, for instance, offers full recyclability while maintaining the rigidity of traditional multi-layer pouches.

6. Cross-Industry Material Borrowing

The smell proof mylar bags sector is adopting aerospace tech:

Graphene Layers: Block odors 3x better than standard mylar

Phase-Change Liners: Regulate internal temps during shipping

Self-Healing Seams: Microcapsules repair minor punctures

Meanwhile, aluminium foil pouch packaging benefits from pharmaceutical innovations—anti-counterfeit holograms and child-resistant zippers now appear on premium coffee and cocoa products.

7. The Personalization Paradigm

Digital printing enables hyper-customized flat bottom box pouch solutions:

Variable Data Printing: Batch-specific artwork celebrating harvest seasons

Edible QR Codes: Printed with coffee bean extract on compostable coffee bags

Localized Flavors: Region-specific designs for global chocolate powder pouch lines

CaféChain’s AR-enabled smell proof mylar bags let customers explore coffee origins via 3D farm tours—a feature that increased dwell time on their app by 70%.

The Future: Zero-Waste and Connected

Tomorrow’s flat bottom box pouch might feature:

🌱 Self-Degrading Timers: Pouches that compost automatically post-expiry

📡 Waste Tracking RFID: Monitoring recycling compliance through the chain

♻️ Circular Design Hubs: Vending machines grinding used compostable coffee bags into planters

Strategic Takeaways

1️⃣ Adopt mono-material flat bottom box pouch designs to future-proof against regulations

2️⃣ Pilot mycelium-lined compostable coffee bags for eco-premium positioning

3️⃣ Integrate smart zippers in aluminium foil pouch packaging to boost DTC loyalty

In an era where packaging must be both functional and philosophical, the flat bottom box pouch and its kin aren’t just containers—they’re brand ethos incarnate. From locking in the aroma of smell proof mylar bags to enabling guilt-free disposal of compostable coffee bags, the industry’s progress proves sustainability and sophistication can share the same shelf.

You can visit our website to know more about our flexible packaging pouch: