Innovative Printed Coffee Bags with Valve: The New Standard in Freshness-Driven Branding

In the competitive world of specialty coffee, printed coffee bags with valve have become non-negotiable for roasters aiming to balance artisanal quality with commercial success. These innovative packages combine precision degassing technology with high-impact branding, addressing two critical consumer demands: peak freshness and visual storytelling. As sustainability regulations tighten and e-commerce reshapes retail, the 2024 packaging landscape rewards brands that merge functional engineering with eco-conscious creativity.

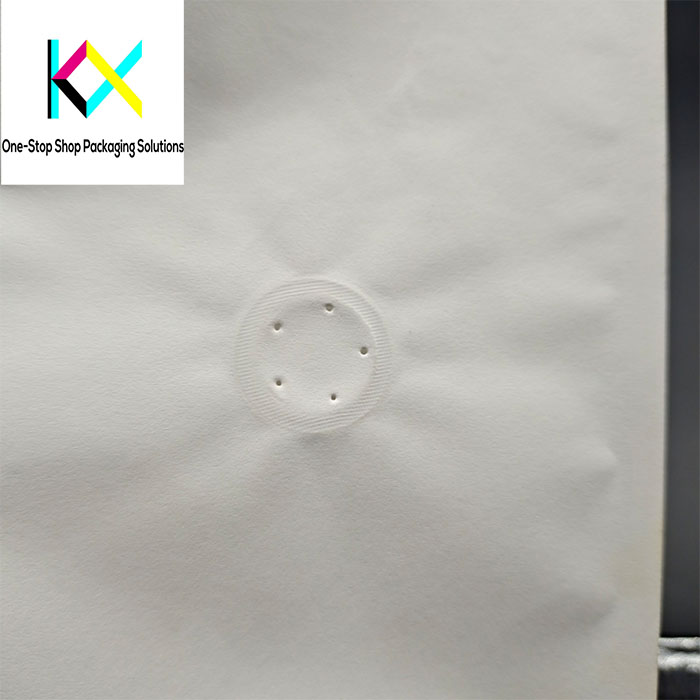

The Science of Freshness: Why Valves Matter

The humble valve in printed coffee bags with valve has evolved into a precision tool for roasters. Modern iterations now offer:

Smart Pressure Control: Micro-adjustable valves that optimize CO2 release based on altitude and humidity

AromaLock™ Tech: Nano-filter layers preventing oxygen ingress while allowing gas escape

Recyclable Valve Designs: PP-based valves compatible with curbside recycling streams

Leading brands like Blueprint Coffee saw a 23% reduction in returns after switching to printed coffee bags with valve featuring humidity indicators. The valve’s role has expanded from functional component to freshness communicator, with some bags using color-changing valve caps to signal optimal brewing time.

Coffee Bean Packaging Bags: Beyond Basic Barriers

While valves dominate freshness tech, the coffee bean packaging bags themselves are undergoing a materials revolution:

Marine-Degradable Films: Breaking down in seawater within 24 months

Upcycled Content: Bags using 30% repurposed coffee chaff in laminate layers

Blockchain-Enabled Inks: QR codes tracing beans from farm to valve

The shift toward mono-material coffee bean packaging bags (achieving 94% recyclability) aligns with EU’s PPWR legislation while maintaining the 18-month shelf life premium markets demand.

Sweet Synergies: Candy Packaging Insights

The innovations driving custom candy packaging bags directly influence coffee tech:

AR-Enhanced Foils: Scanning a chocolate bar wrapper triggers coffee pairing tutorials

Child-Resistant Zippers: Adapted for cannabis-infused coffee products

Biodegradable Glitters: Eco-friendly shimmer for seasonal blends

Bean & Bar Chocolate Co. boosted Q4 sales by 41% using custom candy packaging bags techniques on limited-edition mocha blends—proof that cross-category inspiration drives results.

Protein Packaging Parallels: Lessons for Coffee

The protein powder packaging bag sector’s fight against clumping and moisture offers valuable insights:

Electrostatic Liners: Borrowed from vegan protein bag tech to prevent coffee static

Desiccant-Integrated Seals: Moisture traps hidden in valve assemblies

Grip-Texture Films: Non-slip surfaces for busy café environments

MuscleGrind’s compostable vegan protein bag material is now being tested for coffee by Roast Revolution, potentially creating home-compostable coffee bags that degrade in 90 days.

The E-Commerce Edge

As DTC coffee sales surge, printed coffee bags with valve must withstand logistical gauntlets:

Puncture-Resistant Bases: 3-ply bottoms surviving 15ft drops

Flat-Lay Valve Designs: Preventing damage during automated packaging

Ice-Resistant Inks: Withstanding freezer storage for cold brew concentrates

Combat Coffee’s coffee bean packaging bags now feature integrated bubble cushioning—reducing shipping damage by 68% while eliminating plastic fillers.

Sustainability Meets Shelf Appeal

The 2024 consumer expects eco-innovation without aesthetic compromise:

-

Algae-Based Inks: Carbon-negative printing for printed coffee bags with valve

-

Seed Paper Tags: Plantable batch information cards

-

Digital Watermarks: Hidden recycling instructions scannable at processing plants

GrindZero’s vegan protein bag-inspired coffee packaging uses mushroom mycelium valves—a fully compostable alternative trending in specialty markets.

The Customization Revolution

Modern custom candy packaging bags techniques are elevating coffee branding:

-

Holographic Valves: Refracting light to show roast dates

-

Thermochromatic Inks: Revealing tasting notes when warmed

-

Edible Branding: Rice paper labels dissolving in brewing water

Death Wish Coffee’s AR-enabled printed coffee bags with valve let users visualize flavor profiles—a tech borrowed from premium protein powder packaging bag marketing.

Future-Forward Packaging

The 2025 horizon promises:

-

Self-Healing Films: Microscopic polymers repairing valve seal microtears

-

AI-Optimized Designs: Algorithms balancing valve size, bag dimensions, and roast profile

-

Crowdsourced Art: Customers designing limited-run custom candy packaging bags via apps

Your Bag as Brand Ambassador

Every element of printed coffee bags with valve now serves dual purposes:

-

Valves as freshness guardians and interactive touchpoints

-

Inks conveying brand ethos through sustainable chemistry

-

Seals building trust via tamper evidence and ease of use

From coffee bean packaging bags that tell farm stories to vegan protein bag materials repurposed for ethical brews, the packaging revolution is here.

Ready to Brew Change?

Test compostable valves with small-batch roasts

Pilot AR labels with loyalty program members

Benchmark against protein powder packaging bag durability standards

The brands winning 2024’s coffee wars aren’t just selling beans—they’re delivering multi-sensory experiences sealed in innovation. Your move.

You can visit our website to know more about our compostable pouch:

and you can also visite our Youtube to know more.