Is CMYK Right for Digital Printing Packaging?

When talking about digital printing packaging, some confusion arises between RGB and CMYK. Many customers do not know the type of color space produced by digital printing hence they get confused when printing images. Now lets KX package talk about CMYK and RGB for digital printing on flexible packaging to you.

What is CMYK and RGB?

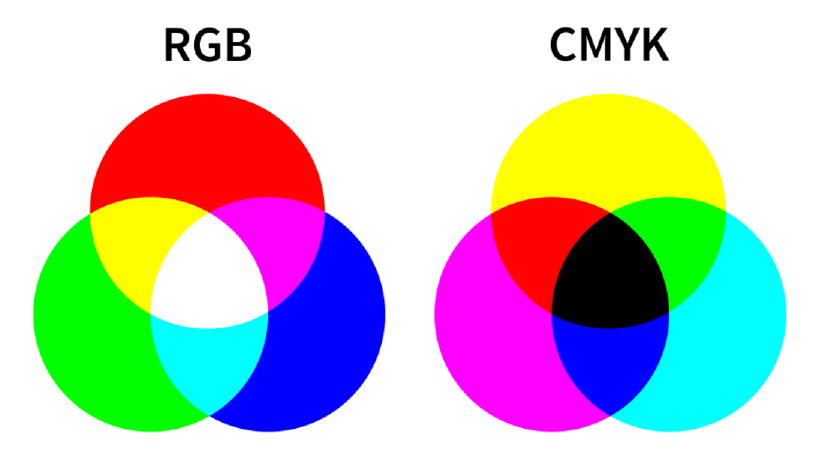

Both CYMK and RGB are color descriptions. CMYK represents Cyan, Magenta, Yellow, and Key (black). By mixing the four colors in varying amounts, millions of others shades are produced in the printed material.

RGB describes the colors of images that are viewed on the monitor. It is the abbreviation for Red, Blue, and Green. The RGB shades are light and when mixed in different quantities, millions of shades are created on the monitor. It is worth noting that all the images viewed on the monitor are RGB except if a conversion to CYMK has been done.

When we try to understand the concepts, they are presented in a challenging way, and we get more apprehensive about learning about them. However, in this article, we will explain the RGB and CMYK color modes in a more straightforward way so that you can use them in the best way.

How to use CMYK for printing?

There are certain times and file formats where you should use CMYK color mode. However, you should avoid doing so other times unless you know which format would be the best.

You need to understand a simple rule: you should always opt for CMYK when a design needs to be printed. CMYK color helps to recreate a design or a style in a more accurate way, to support a colorful package bag to customers.

It would be best if you choose CMYK for the following project types:

Printed Packaging Design

Any packaging design that will be printed digitally, (and some which will beflexographic vs rotogravure), should be setup with CMYK. It should be noted that like a onion, color space selection is complex, and we haven’t address PMS colors in this article, but as a rule of thumb, the best place to start with packaging design is using CMYK.

Merchandises and materials

The merchandise and packaging bags that need to be oriented should be included in the CMYK list, such as products, paper envelopes, collection printed samples, menus, packaging, clothing or even hats.

What is the applications of CMYK in packaging?

RGB is now exclusively used on digital screens to reflect real-life images.

This is now typically not used for printing on packaging and it is recommended to switch your design files to the CMYK color system when designing packaging on software such as Adobe illustrator.

This will ensure more accurate results from the screen to the final product.

The RGB color system may display colors that can’t be matched effectively by printers resulting in inconsistent printing when producing branded packaging.

The CMYK color system has become a popular choice for packaging as it consumes less ink overall and provides a more accurate color output.

Custom packaging is efficient with offset printing, flexo printing, and digital printing using the CMYK color system and creates consistent brand colors for exceptional branding opportunities.

About the digital printing, KX package is adopt HP Indigo 25000 machine to printing the flexible packaging, it has an auto color correction function, and the printing effects are better.

Still not sure if CMYK is right for your packaging bags?

Get custom packaging in contact with us today and find the perfect color-matching system for your custom packaging project!