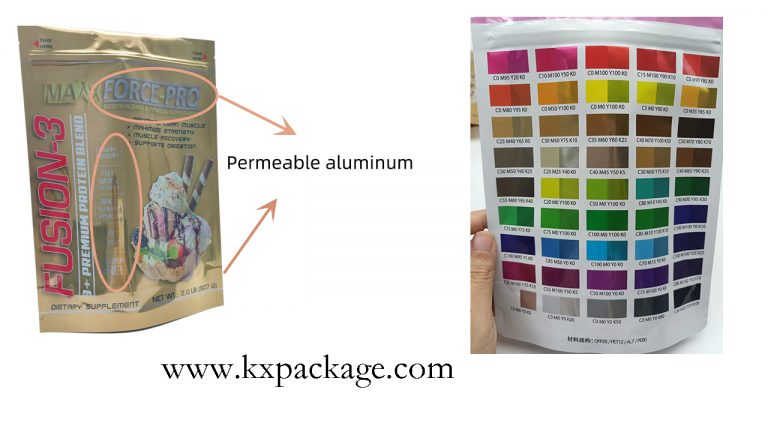

Permeable Aluminum Packaging in Digital Printing

Permeable aluminum is a process used in digital printing to create metallic effects on packaging materials. It involves printing a layer of aluminum ink onto the packaging material, which creates a metallic sheen and enhances the visual appeal of the packaging.

What is permeable aluminum packaging?

The permeable aluminum process involves using a special type of ink that contains aluminum particles. The ink is printed onto the packaging material using a digital printing press, which applies the ink in a thin layer. The ink is then cured using heat, which causes the aluminum particles to bond with the packaging material.

The result is a metallic effect that is similar to traditional aluminum foil, but with the added benefit of being more eco-friendly. Permeable aluminum is a sustainable alternative to traditional aluminum foil, as it can be printed on compostable packaging materials and can be recycled along with the packaging.

Permeable aluminum packaging is a popular choice for packaging products such as coffee, tea, and snacks, as it enhances the visual appeal of the packaging and helps to differentiate the product on the shelf. It is also a cost-effective alternative to traditional aluminum foil, as it does not require additional materials or processes to create the metallic effect.

What is the material structure that can be used for permeable aluminum packaging?

The permeable aluminum process must rely on the reflective effect of the metal film (glossy aluminized film, laser aluminized film, pure aluminum foil…), combined with the transparent color of the hollow printing (not whitening), it can produce color with metallic luster. It is equivalent to the effect of hot silver and hot stamping on paper!

Permeable aluminum packaging is a common form of packaging, which usually consists of multiple layers of materials. The following are common material structures that can be used to make permeable packaging:

OPP/AL/PE: This structure consists of three layers of material, the outer layer is OPP film, the middle layer is aluminum foil, and the inner layer is polyethylene film. This structure has good moisture-proof, anti-oxidation, and anti-ultraviolet properties, and is suitable for packaging coffee, tea, snacks and other products.

PET/AL/PE: This structure consists of three layers of material, the outer layer is PET film, the middle layer is aluminum foil, and the inner layer is polyethylene film. This structure has good moisture-proof, anti-oxidation and anti-ultraviolet properties, and is suitable for packaging food, health care products and other products.

Paper/AL/PE: This structure consists of three layers of material, the outer layer is paper, the middle layer is aluminum foil, and the inner layer is polyethylene film. This structure has good moisture-proof, anti-oxidation and anti-ultraviolet properties, and is suitable for packaging coffee, tea, snacks and other products.

PLA/AL/PLA/PE: This structure consists of four layers of material, the outer and inner layers are PLA film, the middle layer is aluminum foil, and the inner layer is polyethylene film. The structure is biodegradable and suitable for packaging organic food, natural health products and other products.

In general, the material structure of permeable aluminum packaging can be selected according to the characteristics and needs of the product, but it is usually composed of multi-layer materials to provide better protection and protection performance.

In digital printing, the effects of common packaging VS permeable aluminum packaging:

Translucency: Permeable aluminum packaging has a certain degree of translucency, and can pass through a certain amount of light so that the products in the package can be seen. Common packaging has no light transmission and cannot transmit light. The product can only be displayed through the logo and pattern on the outside of the packaging.

Moisture resistance: Permeable aluminum packaging has good moisture resistance, which can effectively prevent the products in the package from getting damp. The moisture resistance of common packaging is relatively poor, and other materials need to be used to improve the moisture resistance.

Oxidation resistance: Permeable aluminum packaging has good anti-oxidation performance, which can effectively prevent the products in the package from being oxidized. The oxidation resistance of common packaging is relatively poor, and other materials need to be used to improve oxidation resistance.

Visual effect: Transparent aluminum packaging can improve the visual effect of the product and make the product more attractive. The visual effect of common packaging is relatively poor, and other methods are needed to improve the visual effect of the product.

Permeable aluminum packaging can provide better protection and protective performance, and can also improve the visual effect of the product, but the cost is relatively high. The cost of common packaging is relatively low, and it is suitable for some products that do not require special protection.