The Future of Flexible Packaging: Embracing Digital Printing, Recyclable, and Biodegradable Solutions

The packaging industry is undergoing a significant transformation, driven by advancements in technology and an increasing focus on sustainability. Among the various segments of this industry, flexible packaging stands out for its adaptability, efficiency, and environmental benefits. Companies specializing in flexible packaging are now leveraging digital printing technology and developing recyclable and biodegradable packaging solutions to meet the evolving needs of both consumers and businesses. This article explores the technological innovations and industry trends that are shaping the future of flexible packaging.

Digital Printing in Flexible Packaging

Digital printing technology has revolutionized the flexible packaging sector by offering unparalleled advantages over traditional printing methods. One of the primary benefits of digital printing is its ability to produce high-quality, vibrant graphics with exceptional detail and accuracy. This is particularly important for brands looking to create visually appealing packaging that stands out on store shelves.

Moreover, digital printing is highly efficient for short runs and customizable designs. It allows for quick turnaround times, reducing the time-to-market for new products. This flexibility is essential in today’s fast-paced market where consumer preferences can change rapidly. Additionally, digital printing eliminates the need for printing plates, which reduces setup costs and minimizes waste, making it a more sustainable option.

Recyclable Flexible Packaging

As environmental concerns continue to rise, the demand for recyclable packaging solutions has increased significantly. Recyclable flexible packaging is designed to be processed through existing recycling systems, ensuring that the materials can be reused rather than ending up in landfills.

To achieve true recyclability, packaging manufacturers are focusing on using mono-materials or compatible polymers that can be easily separated and recycled. For instance, polyethylene (PE) and polypropylene (PP) are commonly used materials that can be recycled effectively. Innovations in adhesives and inks are also crucial, as they need to be compatible with recycling processes without contaminating the recycled material.

Furthermore, clear labeling and consumer education are essential to ensure that recyclable packaging is disposed of correctly. Brands are increasingly adopting standardized recycling symbols and providing guidance on how to recycle their packaging, helping to close the loop on the recycling process.

Biodegradable Packaging Solutions

In addition to recyclability, biodegradable packaging is gaining traction as a sustainable alternative. Biodegradable packaging materials are designed to break down naturally over time, reducing the environmental impact of packaging waste. These materials are typically derived from renewable sources such as plant-based polymers, which can decompose under specific conditions.

Polylactic acid (PLA) and polyhydroxyalkanoates (PHA) are examples of biodegradable polymers used in flexible packaging. These materials offer comparable performance to traditional plastics but with the added benefit of being compostable. However, it is important to note that biodegradable packaging requires proper disposal in industrial composting facilities to achieve optimal degradation.

Industry Trends and Future Outlook

The flexible packaging industry is poised for continued growth, driven by technological advancements and a shift towards more sustainable practices. Key trends shaping the future of this industry include:

1.Sustainable Packaging Initiatives: Companies are increasingly committing to sustainability goals, such as reducing plastic waste and lowering carbon footprints. This has led to the development of innovative packaging solutions that prioritize environmental responsibility.

2.Consumer Demand for Eco-Friendly Products: Consumers are becoming more environmentally conscious and prefer products with sustainable packaging. This demand is driving brands to adopt recyclable and biodegradable packaging options.

3.Regulatory Changes: Governments around the world are implementing stricter regulations to reduce plastic waste and promote recycling. These policies are pushing the packaging industry to innovate and adopt more sustainable practices.

4.Advancements in Material Science: Ongoing research and development in material science are leading to the creation of new, sustainable materials that offer the same functionality as traditional plastics. These advancements are crucial for the widespread adoption of eco-friendly packaging.

5.Integration of Smart Packaging: The incorporation of smart packaging technologies, such as QR codes and RFID tags, enhances the functionality of flexible packaging. These features can provide consumers with additional information about the product and its sustainability credentials.

In conclusion, the future of flexible packaging lies in embracing digital printing technologies and developing recyclable and biodegradable solutions. By prioritizing sustainability and leveraging technological innovations, the flexible packaging industry can meet the growing demands of consumers and regulatory bodies, while contributing to a more sustainable future. As these trends continue to evolve, companies that adapt and innovate will be well-positioned to lead the industry and drive positive change.

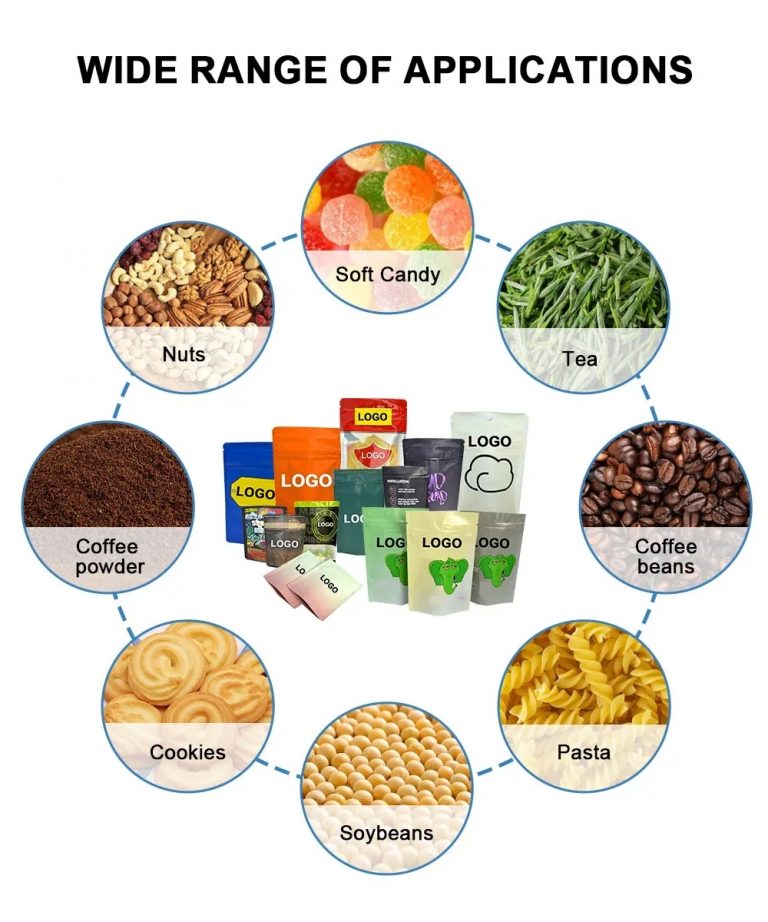

We Kexin Packaging can offfer different types of flexible packaging including the digital printing, recyclable packaging and compostable packaging.

Click here to know more about us and you could also visit our Youtube to see products we made.